TrackScan-P Optical 3D Measurement System

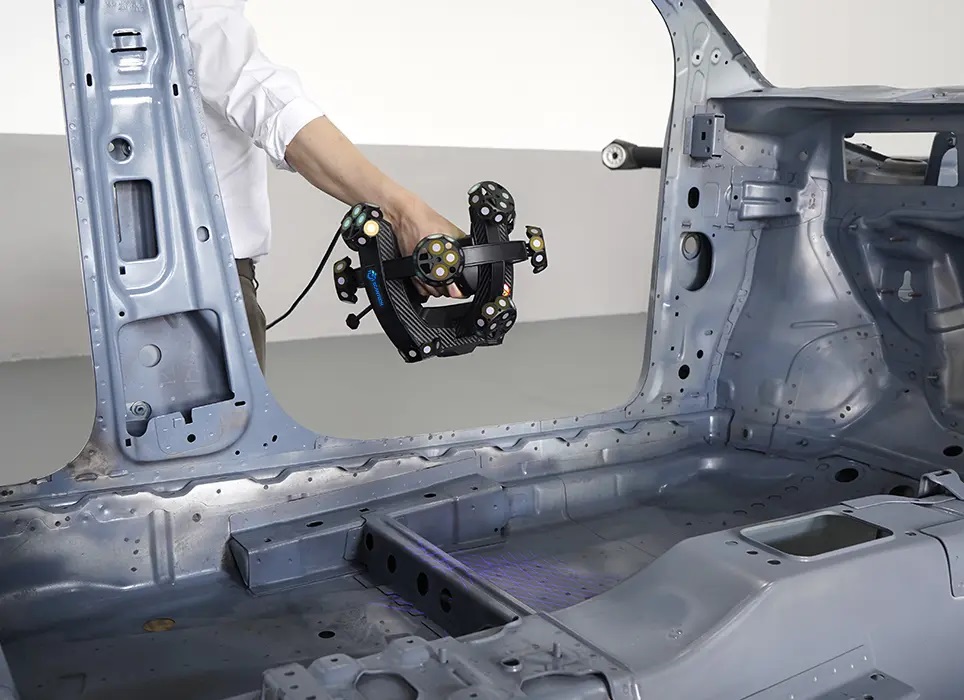

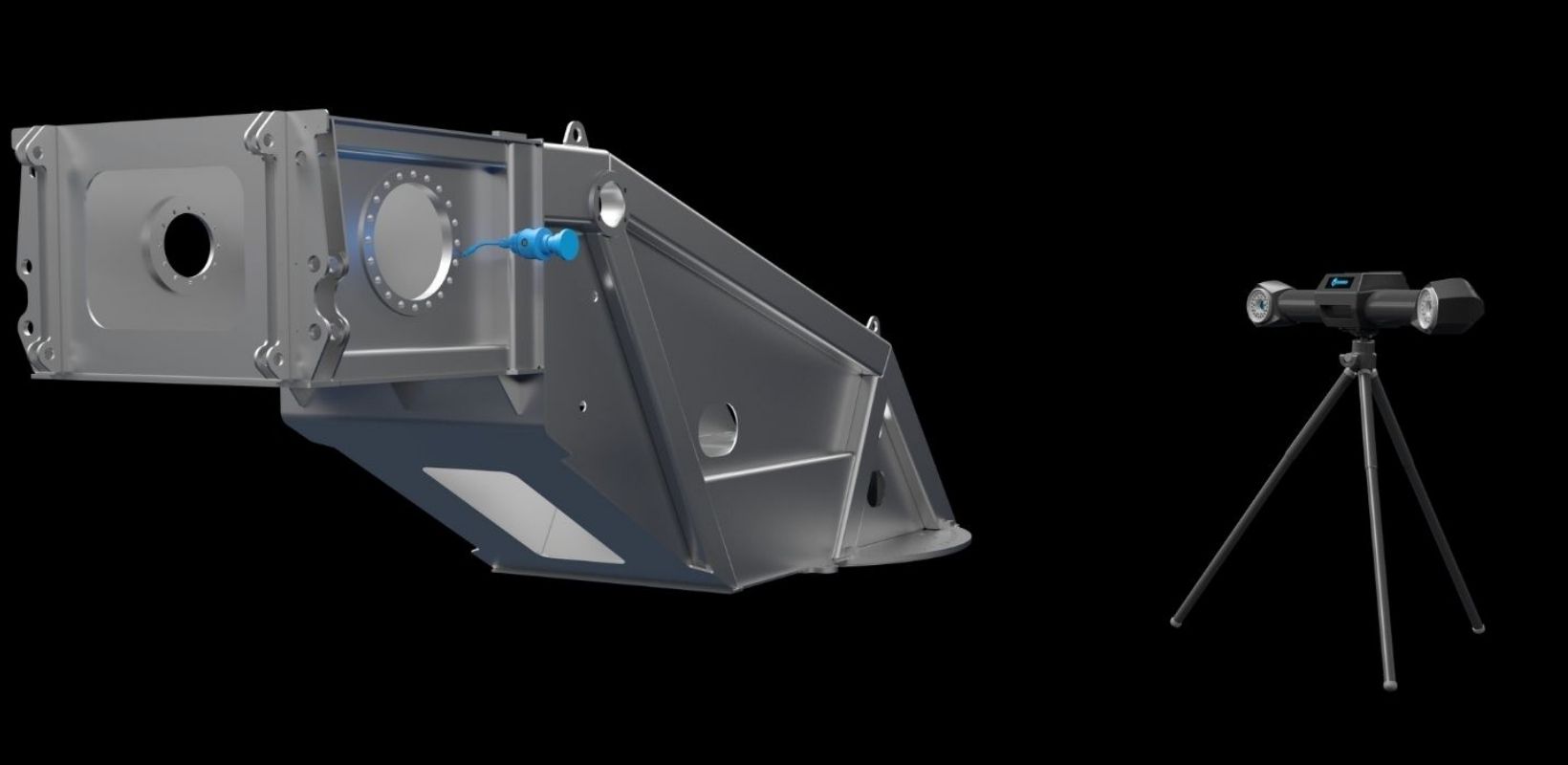

Engineered with intelligent optical tracking measurement and high-resolution cameras, TrackScan-P can precisely measure parts without having to stick reference targets. This optical 3D measurement system, consisting of a portable 3D scanner and an optical tracker i-Tracker, suits well for 3D scanning large-scale objects. It can be widely applied for quality control, product development, reverse engineering, and more in industries such as aerospace, automotive, rail transport, and mold.

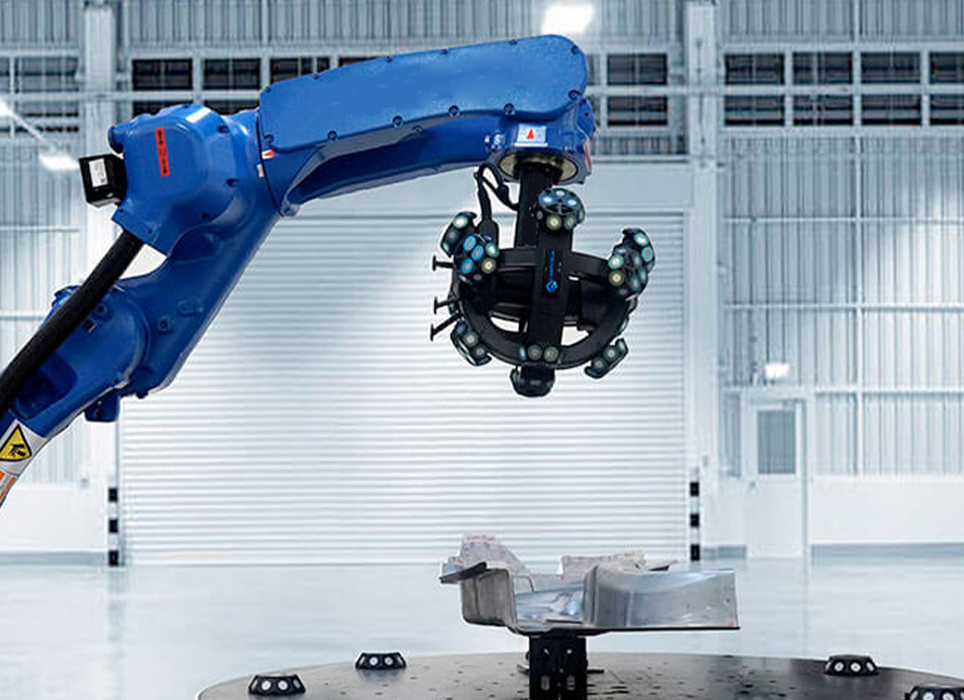

By combining it with additional modules, it can enable extendable applications. It can be paired with an auxiliary light module to inspect circles, grooves, and machined holes of stamping parts. With a tracking T-Probe, it conducts precise contact measurements for edges, circles, and grooves. When being mounted onto a robot arm, it is an optimal choice for intelligent and automated 3D inspection.

Target-free 3D Scanning

Ultra-fast Measurement

Edge Detection

Extendable Measuring Volume

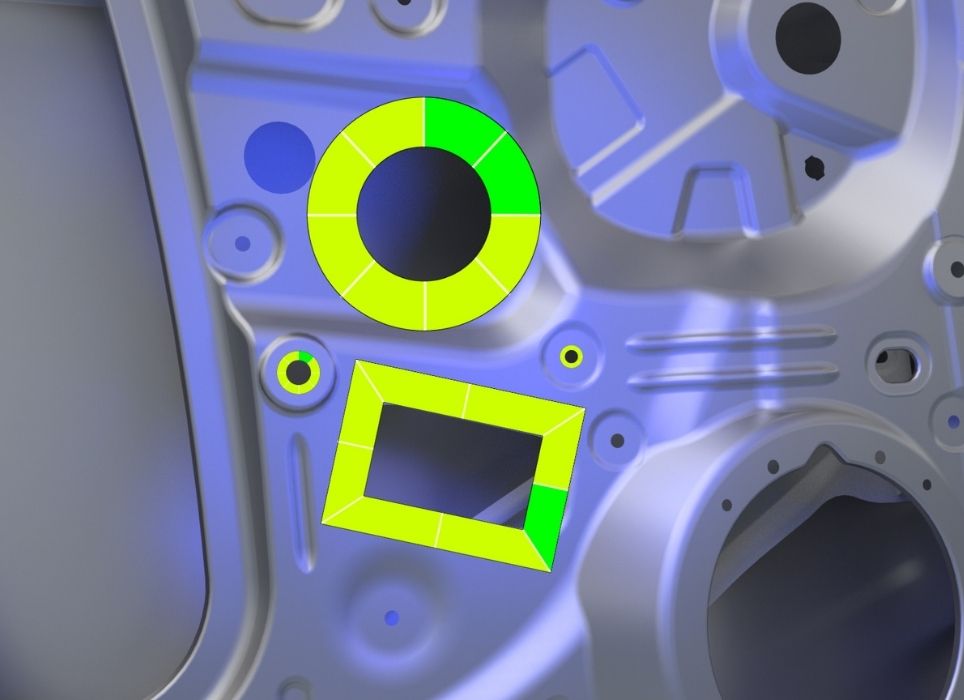

Precise Edge Detection

TrackScan features a stand-out function of instant edge detection. Users can inspect circles, grooves, and machined holes of stamping parts in various finishes on the site without having to import original CAD models.

The efficient edge detection is enabled thanks to its gray value measurement and optional auxiliary light module. Good measurements are ensured by delivering accurate and repeatable hole positions and diameters.

Unrivaled-fast & Detail-maker

By freely switching between multiple working modes, the TrackScan fits different scanning situations with an accuracy of up to 0.025 mm and an ultra-fast measurement rate of up to 2,600,000 measurements/s. Its 7 parallel blue laser lines perform well for capturing details. A single blue laser line aims to collect 3D data of deep holes and hard-to-reach areas efficiently.

Optical Tracking for Instant 3D Scanning

TrackScan-P 3D system’s optical tracking allows users to start scanning instantly without having to stick targets, significantly improving efficiency and decreasing costs.

Strong Adaptability

Made from aerospace-grade materials, it is sturdy and reliable. It also boasts a strong anti-interference capability to operate smoothly regardless of vibrations or thermal variations. Due to its advanced algorithm, TrackScan is robust in capturing 3D data of reflective and dark surfaces.

Extendable Applications

Technical Specifications

| Type | TrackScan-P550 | TrackScan-P542 | |

| Scan mode | Ultra-fast scanning | 21 blue laser crosses | 17 blue laser crosses |

| Hyperfine scanning | 7 blue parallel laser lines | ||

| Deep hole scanning | 1 blue laser line | ||

| Accuracy(1) | Up to 0.025 mm (0.0009 in) | ||

| Measurement rate up to | 2,600,000 measurements/s | 2,200,000 measurements/s | |

| Scanning area up to | 500 mm × 600 mm (19.7 in × 23.6 in) |

||

| Laser class | ClassⅡ (eye-safe) | ||

| Resolution up to | 0.020 mm (0.0008 in) | ||

| Volumetric accuracy(2) | 10.4 m³ | 0.060 mm (0.0024 in) | |

| 18.0 m³ | 0.075 mm (0.0030 in) | ||

| Volumetric accuracy (With MSCAN photogrammetry system) | 0.044 mm+0.012 mm/m (0.0017 in + 0.00014 in/ft) |

||

| Single-point repeatability of tracking T-Probe | 0.030 mm (0.0012 in) | ||

| Hole position accuracy | 0.050 mm (0.0020 in) | ||

| Object Size (Recommend) | 100 mm – 8000 mm (3.9 in – 315.0 in) |

||

| Stand-off distance | 300 mm (11.8 in) | ||

| Depth of field | 400 mm (15.7 in) | ||

| Output formats | .stl, .obj, .ply, .asc, .igs, .txt, .mk2, .umk and etc. | ||

| Operating temperature range | -10°C–40°C (14℉-104℉) | ||

| Operating humidity (Non-condensation) | 10%–90% RH | ||

| Interface mode | USB 3.0 | ||

| Certification | CE, UL | ||

| Patents | CN106500627,CN106500628,CN206132003U,CN204854633U,CN204944431U,CN204902788U,CN204963812U,CN204902785U,CN106403845,US10309770B2,CN204854633U,CN105068384B,CN105049664B,CN106403845B,CN214375417U,CN214379242U,CN214379241U,CN109000582B,CN112802002B,CN210567185U,CN211121096U,CN214149174U,CN114001671B,CN114001696B,CN114554025B,CN114205483B,US10309770B2,US11060853B2,KR102096806B1,EP3392831B1 | ||

(1) ISO 17025 accredited: Based on VDI/VDE 2634 Part 3 standard and JJF 1951 specification, probing error (size) (PS) performance is evaluated.

(2) ISO 17025 accredited: Based on VDI/VDE 2634 Part 3 standard and JJF 1951 specification, sphere spacing error (SD) performance is evaluated.

Ready To Get Started?

Rebuild our 3D world with the most advanced 3D scanning system available.

Request A DemoWhat’s the best 3D solution for your business?

Boost your business with 3D digitization technology.

Ask An Expert BrochureHigh-tech 3D Scanners

Scantech’s handheld 3D scanners power the 3D scanning services. These instruments can obtain precise point clouds, which can be triangulated into a polygon mesh or STL file.

Due to their high precision, versatility, and portability, they can fulfill various metrology-grade 3D scanning projects.