Glopho Photogrammetry Software

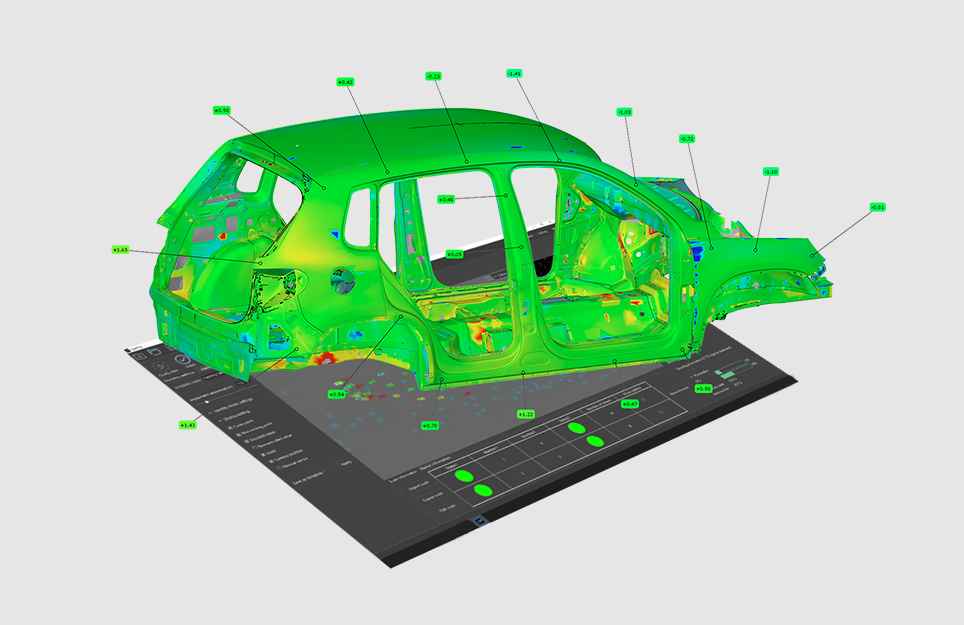

Glopho is a powerful photogrammetry software that works in unison with Scantech’s 3D measurement systems to conduct accurate coordinate measuring for medium-to-large-scale parts. It brings photogrammetry, real-time display, scale bar management, data analysis, and working environment detection into one intuitive environment to navigate the measuring with ease. It is well-suited for applications in various sectors, including automobile, rail transport, and shipbuilding, power generation, heavy industry, and more.

By taking photos from various angles, metrology professionals can stitch precise 3D coordinates of targets and scale bars with the help of Glopho. These targets form a stable backbone structure for later 3D scanning, helping to eliminate alignment errors accumulated over distance. Thanks to its sophisticated algorithm and architecture, the measurement accuracy can reach 0.012 mm/m.

Ultra-high Precision

Intelligent Indication

Movable Scale Bars to Increase Precision

Adaptor for Feature Measurement

Wireless Connection for Cable-free Photogrammetry

User-friendly Interaction

Ultra-high Precision

Glopho offers a complete toolset for all photogrammetry workflows with advanced operational procedure design and a simple user interface. Thanks to its sophisticated algorithms, its coordinate measurement accuracy can be up to 0.012 mm/m. It can automatically exclude targets with high RMS error from calculations to improve accuracy. With robust performance in photogrammetry, it is capable of meeting the requirements of medium-to-large-scale parts.

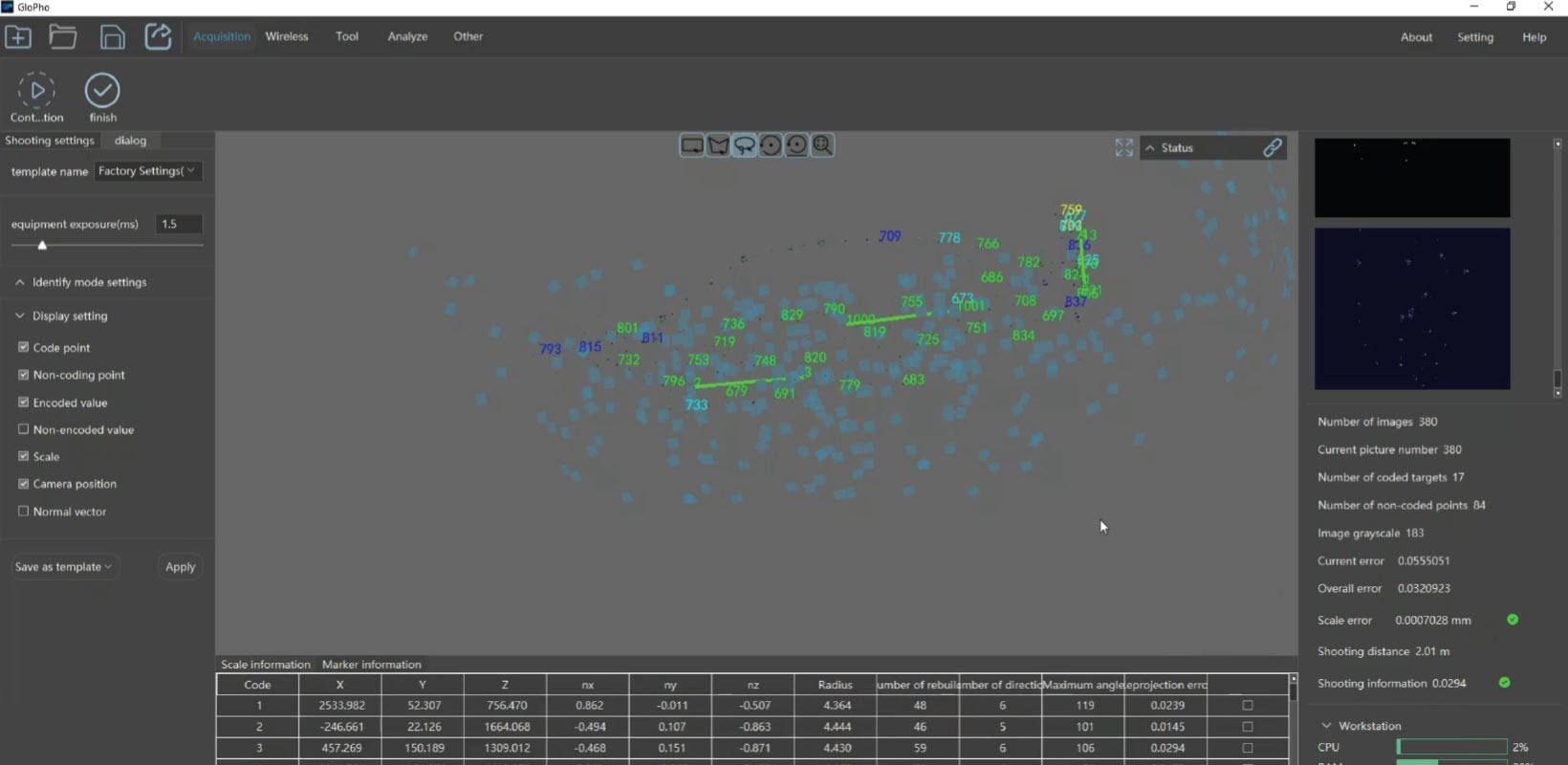

Intelligent Indication

All the information about shooting, such as shooting distance, shooting angles, and numbers of photos taken, show up intuitively on the interface. With coded targets and scale bars shown in five colors to indicate different levels of data acquisition, users can intuitively monitor the shooting status. When errors occur, intelligent indicators pop up. Therefore, users can adjust shooting accordingly or re-shoot targets without sufficient shooting angles to ensure high-precision results.

Movable and Customized Scale Bars

To further enhance the efficiency and increase precision, Glopho supports the use of multiple scale bars to serve as a datum for capturing data for objects longer than 3 meters. After the data of a scale bar is fully captured and saved, users can choose to move the scale bar to a new position. In this way, the precision can be enhanced without the need for extra scale bars. Thanks to its high flexibility, Glopho is compatible with customized scale bars or those not included with it.

Adaptor for Feature Measurement

It supports simple signalizing with standard and customized adaptors for feature measurement. When the process of photogrammetry completes, technicians and engineers can obtain geometric features of the workpiece such as hole boundary, and hole center. It is ideal for measuring inspection tools, holes on sheet metal, and cylindrical parts to elevate the measurement efficiency on large parts.

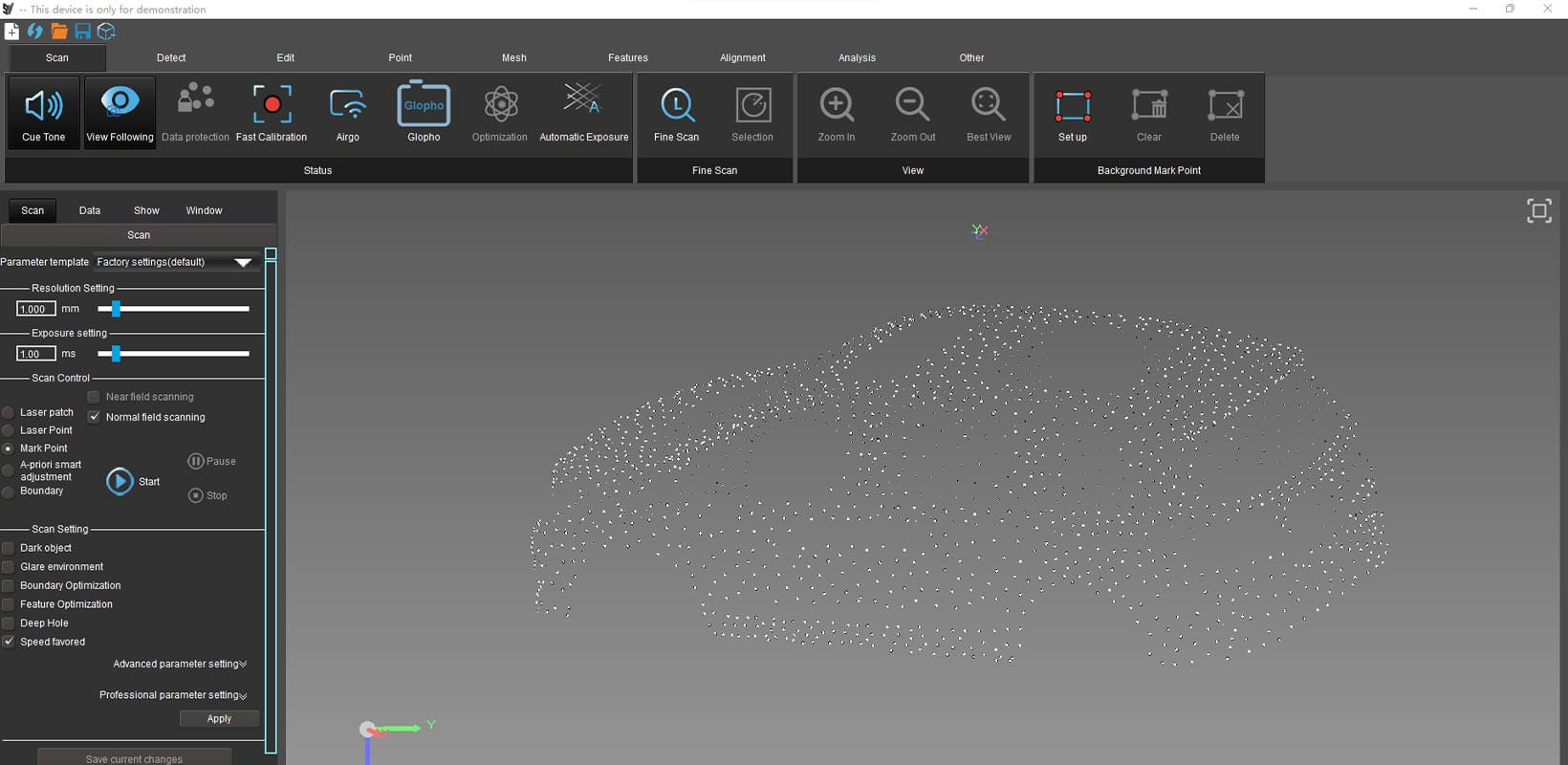

User-friendly Operation

Glopho displays the whole shooting process on the interface so that users can troubleshoot any potential problems. It allows them to resume tasks interrupted by importing project files in one click. With its operating environment diagnostic tool, users can check whether the computer configuration meets the requirements. It also boasts an intuitive user interface and enables users to personalize it by choosing between different layouts.

Workflow

High Flexibility

Glopho can be seamlessly integrated into the high-precision photogrammetry process of Scantech’s 3D measurement systems and connected to wireless communication link AirGo for maximum freedom of movement.

KSCAN

AXE

MSCAN

Ready To Get Started?

Rebuild our 3D world with the most advanced 3D scanning system available.

Request A DemoWhat’s the best 3D solution for your business?

Boost your business with 3D digitization technology.

Ask An Expert BrochureApplication

High-tech 3D Scanners

Scantech’s handheld 3D scanners power the 3D scanning services. These instruments can obtain precise point clouds, which can be triangulated into a polygon mesh or STL file. Due to their high precision, versatility, and portability, they can fulfill various metrology-grade 3D scanning projects.