Tested Solution, Trusted Quality

How to Use 3D Laser Scanners for 3D Inspection?

Capture 3D Data

Fast, accurate, and widely adopted

Create a 3D Model

Detailed, precise, and perfectly presented

Process Data with Inspection Software

Seamlessly connect to various software

Generate an Inspection Report

Intuitive and easy to read

Benefits

Comprehensive, accurate, and efficient solutions to meet the requirements of quality inspection of various parts.

Applications in Various Industries

Scantech has extensive experience in the field of 3D quality inspection. Our handheld 3D scanners are versatile and portable, which can cater to various complex working environments and have a wide range of applications.

Integrity of Data Acquisition

Using Scantech’s portable and handheld 3D scanners, technicians can conduct on-site 3D scanning. These 3D scanners can obtain complete 3D data of complex parts with ultra-high precision and resolution thanks to their advanced algorithms. They can also generate accurate inspection report with full-field data, and comprehensively analyze the deviation of points, lines and planes.

Efficiency, and Double Profits

Our 3D scanners are more flexible to perform various inspection tasks than traditional methods. Customers can use these 3D scanners to inspect parts anytime and anywhere. They can greatly reduce operation sessions without compromising accuracy and efficiency. These 3D scanners can also be mounted on automated 3D measurement systems to inspect in batches. The inspection reports generated are intuitive and easy to understand, which can greatly reduce labor costs and lower threshold of operation.

Applications

Automotive

Scantech has been deeply engaged in the field of automobile manufacturing industry and provides sophisticated inspection solutions for OEMs during the whole cycle time.

Rail Transport and Shipbuilding

A safe journey begins with precise inspection of transports. We provide unparalleled smooth 3D scanning for metrology inspection. By delivering accurate measurement results, our 3D scanning technology can ensure the safe operation of rail transport and ship.

Energy & Heavy Industry

Scantech is empowering the development of the energy industry with advanced 3D technology. We are committed to helping realize the goal of carbon neutrality, promote the upgrading of heavy machinery industry, and further improve intelligent manufacturing productivity.

Mold

Customers can use our handheld 3D scanners to simplify the process of mold inspection, mold preservation and digital archiving, and to inspect molds accurately and reliably.

Medical

Science and technology shape a bright future. Scantech offers 3D solutions that meet the high-precision standard in the field of medical equipment by providing accurate data for doctors and patients.

Scantech Solutions

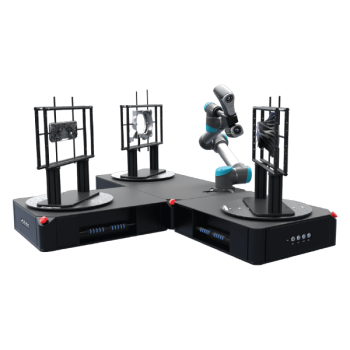

Industrial manufacturers use Scantech’s handheld 3D scanners and automated 3D inspection systems to efficiently perform inspections.

Our industrial handheld 3D scanners such as the KSCAN series, SIMSCAN series, TrackScan series, and AXE series are designed for inspection of high-precision parts. By using handheld 3D laser scanners and non-contact 3D scanning technology, professionals and engineers can obtain accurate 3D point clouds of products. They can also instantly process data with the 3D software ScanViewer. The optimized data can be imported into CAD software for convenient data analysis and rapid and efficient 3D inspection. Besides, Scantech’s automated 3D inspection systems AutoScan series can support inspections in batch and dramatically increase efficiency.

Product Recommendation

Choose the 3D scanner and automated 3D inspection system that fit your inspection needs