Application of KSCAN-MAGIC 3D Scanner in Railway Bridge Inspection

As an important part of structural engineering for rail, the quality of railway prefabricated bridge elements is directly related to the construction quality and rate of progress of railway bridges.

Due to the particularity of bridge construction, many bridge elements are prefabricated in factories, and the quality of prefabricated components of pre-bridges is guaranteed through factory standardized construction procedures, high-precision prefabricated molds, and strict control of various conditions for beam making.

Since there is no other detection method, the deformation status of the prefabricated components after being cast and dried cannot be detected.

The client of this issue is a large state-owned construction enterprise, which mainly undertakes domestic and foreign highway construction projects.

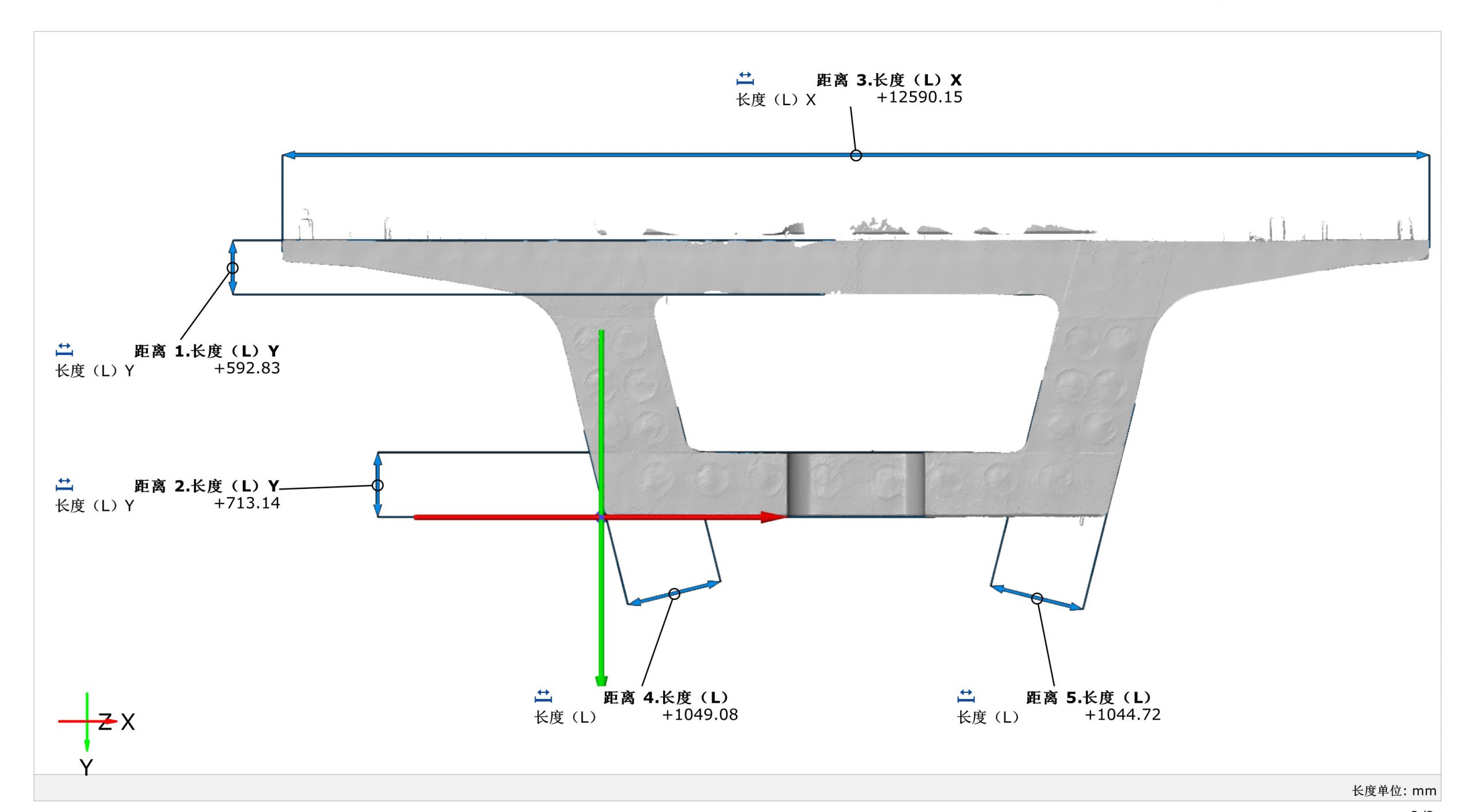

This customer wants to establish an acceptable standard for the railways and subways and light rails and hopes that we can provide a set of 3D digital solutions to help them measure the deformation and position dimensions of the mold after casting, and wants to be the first to applicate it in this industry.

Requirements and difficulties for scanning

● The size of the prefabricated bridge element is large, each section is 24.6 meters in length.

● For outdoor environment scanning, there is strong sunlight, and the temperature changes greatly.

Scan 3D Solutions

Based on the actual application, SCANTECH provides customers with a set of 3D digital solutions that are more suitable for scanning large objects outdoors:

First, use the MSCAN-L15 Photogrammetry System for global localization,

And then use the large area scanning function of the KSCAN-Magic Composite 3D Scanner,

And finally to generate a test report. The entire inspection process of a single prefabricated component only takes 30 minutes, which is highly accepted by customers.

Advantages of the solution

Super high efficiency: 30 minutes to complete the scan detection process

KSCAN-MAGIC’s world’s first infrared laser scanning technology and ultra-high efficiency scanning mode developed for large workpieces can achieve a single scan area of 1440mm*860mm, which greatly increases the scanning speed.

Convenient to hold, super environmental adaptability

It can be moved arbitrarily according to the construction progress with the hand-held operation, and the scanning results are less affected by changes in the on-site environment (temperature, lighting, etc.), which is suitable for outdoor and fieldwork.

Scan Data

Summary

the KSCAN-Magic Composite 3D Scanner can be used not only for the detection of prefabricated bridge elements but also for deformation detection during the operation and maintenance phase of the bridge, which is due to its high efficiency and precise measurement.

It brings new insights into the solutions of the quality monitoring and acceptance of railway bridges.