As an industrial designer in the automotive industry, are you searching for a way to significantly accelerate your daily workflow without compromising precision? Learn how to increase efficiency, maintain accuracy and boost productivity with Scantech’s cutting-edge 3D scanners.

In this blog, we will show you the capabilities of our 3D scanning technology for a variety of automotive customization.

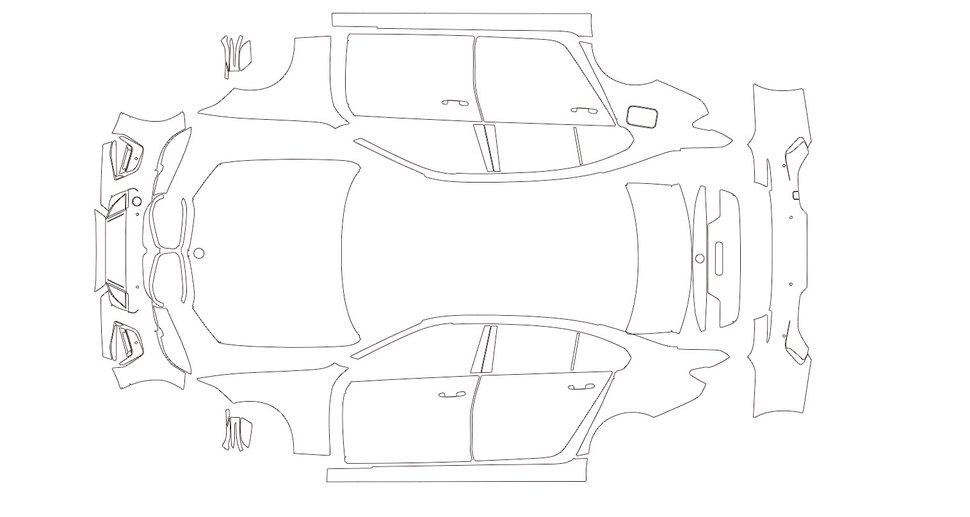

Automotive Paint Protection Film (PPF)

PPF is a urethane material that protects a car’s coat and the paint beneath it from scratches, sunlight exposure, and dirt. PPF in different colors is also a way to show the unique personality and sense of style.

Using specialized software, design specialists create patterns that can be cut onto a film to perfectly fit the cars. What they expect is a pattern that goes up to the edges of the cars close with the least amount of seams left.

It ensures the optimal use of raw materials and makes it easy for technicians to apply PPF to the car.

A precise 3D model of a car can help a designer create a perfect PPF pattern. That is where our portable handheld 3D scanners come in. These compact 3D scanners are easy to use and are reliable in delivering high-quality measurement results.

Capturing precise 3D data of a wide range of cars ensure designers establish a rich database that they can search anytime they want.

How Does It Work?

Tool:

Composite 3D scanner KSCAN-Magic with built-in photogrammetry

Benefits of Using Scantech’s 3D Scanner

KSCAN-Magic can be carried around to conduct on-site 3D scanning thanks to its portability. It’s lightweight and apt for prolonged use without causing much fatigue.

KSCAN-Magic features five working modes, which allow you to scan objects ranging from a coin to an airplane. 3D scanning a car as long as 3 meters won’t be a problem with its built-in photogrammetry.

It’s 1440 mm * 860 mm-scanning area can dramatically reduce the time of capturing 3D data. Its accuracy is up to 0.020 mm, and its resolution is up to 0.010 mm, which ensures the pattern is precise to plot the PPF desired.

KSCAN-Magic can capture dark and reflective surfaces regardless of environmental conditions, whether it is indoors or outdoors. Its robust performance in 3D scanning various finishes makes it easy to capture accurate car data.

Automotive Interior Customization

Applications for automotive interior customization include fit-outs of van interiors, development of accessories such as car floor mats, seat covers, screens for dashboards, navigation, audio, etc.

Traditional Measurement Method

The main challenges of measuring a car are its large size and the significant number of various curves and angles. Traditionally, technicians use a protractor to measure the maximum door opening angle.

When measuring the size and shape of a car door, rolling tape and a telescopic measuring rod are needed. The process is time-consuming and laborious, and the final data collected is sometimes not accurate enough.

Scantech’s 3D Scanners

Our 3D laser scanners conduct non-contact 3D measurements to capture the whole data of the interiors. The measurement is not limited by different shapes and angles so that one instrument can tackle various measurement tasks.

The scanning rate of our 3D scanners can reach a level of million times per second, which hugely saves the time of capturing data. The complete data our 3D scanners deliver can serve as a precise basis for further design of the center console, seat, and mat floor.

How Does It Work?

Tool:

Portable 3D scanner SIMSCAN

Benefits of Using SIMSCAN

With a net weight of 570g, this palm-sized SIMSCAN is flexible enough to scan confined areas.

The SIMSCAN performs well in capturing data of slits and edges due to its shorter distance of two cameras compared to traditional 3D scanners. The shorter camera distance results in a smaller view angle, which ensures that its scanning view is not be blocked, shown as below.

SIMSCAN can scan dark and reflective surfaces without spraying powder thanks to its robust algorithm.

Modification

Here is a briefcase of rear wing customization of GT-R. Take a glimpse into how our 3D scanner can help in modification.

GT-R Rear Wing Customization

Tool:

Composite 3D scanner KSCAN-Magic

Workflow:

- 3D scan the rear wing of GTR and obtain its 3D data

- Create a 3D model

- Virtually assemble the new wing to the original using the 3D model

- Provide higher downward force to ensure more stable driving at high speeds

Benefits of Using KSCAN-Magic

The accuracy of measurement of KSCAN-Magic is as high as 0.020 mm. The high-precision 3D ensures the seamless connection between the newly added part and the original wing, thus improving the vehicle’s stability.

KSCAN-Magic is a powerful tool to capture data on dark and reflective surfaces. When measuring the black rear wing, it delivers complete and accurate 3D data of the part with clear details.

Other Applications

In addition to the cases above, there are other possibilities that industrial designers can explore. Using 3D scanning, they can customize wide-body, caravan, sports cars, chassis suspension systems, exhausts, etc.

Wide Body Modification

Our 3D scanners offer designers greater flexibility to customize different parts and components, which is also a way to reduce the time needed to design. With the new technology entering the industry of customization, customers see more possibilities to customize to suit their personalities.