There are tens of thousands of ships sailing across oceans every day. Some challenges such as lack of right skilled resources and industry knowledge come in the way of ship design and periodic inspections.

Thanks to its high precision and speed, handheld 3D laser scanner has great potentials in accelerating the product development of ships and streamlining their quality control process.

It supports non-contact and non-destructive detection of ships and can be used on site. In this blog, we will discuss How can 3D scanning help in the design and quality control of ships.

Ship design

In the initial stage of ship design, the design is done by using the geometries of a parent ship. The parent ship serves as a reference for the new vessel’s geometry which influences its hydrostatics and strength. A common issue arising in the design is the lack of original 3D drawings of a parent ship.

In this case, a typical approach to obtain data of a ship is to measure it with traditional tools such as tapes and rulers. An architect has to apply his knowledge and experience to create a set of ship lines with sufficient accuracy.

These lines will be then used for later calculation. However, these measurements are time-consuming and burden-some.

With respect to time and cost, 3D scanners that capture the whole 3D data of a ship have become competitive in design and product development.

Case: yacht design

Scantech has helped a customer to redesign his yacht by providing a high-tech 3D scanner. Keeping up to date with the latest design trends and customizing a yacht is a symbol of exclusivity and luxury lifestyle for most of yacht owners.

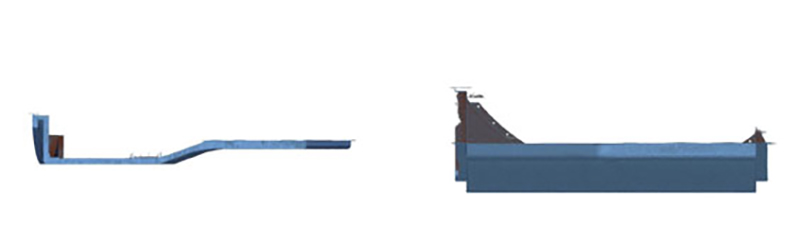

In this case, the customer had no original 3D drawings of his yacht. He hoped to obtain 3D data of the yacht through 3D scanning and generate 3D models through professional 3D software. These reliable 3D data can be used for later development and redesign of his yacht.

The length of the yacht to be scanned is as long as 11 meters. If the scanning area of the 3D scanner is not large enough, the alignment errors will accumulate over the distance. Therefore, the measurement results would fail to meet the requirements of accuracy.

Scantech’s handheld 3D scanner KSCAN, with a built-in photogrammetry system, aims to solve this problem. It is one of the first scanners that have a large-range scanning mode powered by infrared parallel lasers.

It can scan an area as large as 1440 mm x 860 mm. Besides, with an accuracy of up to 0.020 mm, it suits well for scanning large objects.

It took about 1 hour to complete the scanning of the whole ship. Compared with traditional measurement methods, KSCAN greatly simplified the modeling of ships for designers and it highly improved the efficiency of the shipbuilding industry.

For ship manufacturers, the model generated by professional 3D software can not only be used for product design and manufacturing but also used for digital display.

It helps the manufacturers to display their products in a more intuitive way and stand out in this competitive market. It can also be used as the digital archiving of yachts to provide a solid data basis for later modification.

Quality Control of Ship

The ship has complex structures, a wide range of types, and a high requirement for precision. A quick response to the requirements of design and inspection is among the top considerations of ship manufacturers to maintain an edge in the competitive market.

With high efficiency and accuracy, 3D scanning technology can effectively solve the problems for manufacturers.

At the request of a ship manufacturer from South Korea, Scantch provides a 3D solution with TrackScan, a 3D scanner with optical tracking, and no need for sticking markers. The customer used this TrackScan to obtain 3D data of the bottom of the cabin and detect its quality.

In the process of ship manufacturing, due to the constraints caused by limited skills, time, and unstable shop-floor conditions, the dimensions of the ship will inevitably deviate from the nominal dimensions.

To control the quality of ships produced and reduce the assembly errors, it is important to obtain the 3D data of ships and their tolerances efficiently and quickly.

Case: ship inspection

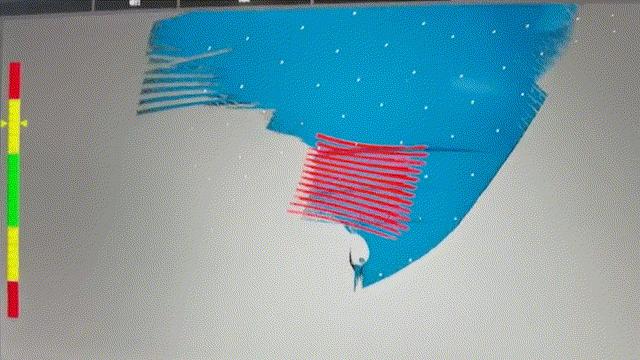

Scantech’s 3D scanner TrackScan conducted an on-site 3D scanning with no need for markers or auxiliary equipment. The data of the ship were captured efficiently and a report was then generated to identify parts that need to be repaired or modified.

The typical approach when performing ship checks is to bring technicians on board to measure it with tools such as a straight ruler, tape measures, level meter. This highly manual and tool-dependent method is costly and time-consuming.

The measurement result can not be guaranteed because of human factors, which may affect the manufacturing of ships.

The 3D scanning technology can improve the precision, quality, and efficiency of shipbuilding and greatly shorten the time-to-market.

Case: propeller inspection

Scantech has provided 3D quality inspection solutions for the propeller of a large-scaled ship to help the company control its quality.

The propeller of a massive ship mainly consists of a hub, a shank, and blades, all of them are of large sizes. The quality of these components directly affects the later assembly, and also the functioning of the propeller.

Therefore, it is necessary to inspect every component precisely right after it is produced. In this way, manufacturers can ensure the quality of products and reduce costs caused by unqualified products.

Technicians from Scantech used a TrackScan 3D scanner to scan the propeller. With its super adaptability and sensitivity to environments, TrackScan easily scanned both bright and dark surfaces and obtained accurate 3D data of workpieces.

By comparing it against the original CAD drawings, an intuitive report of the inspection was obtained.

More applications

The massive Ever Given container ship, which weighs 440 million pounds, had been stuck in the Suez Canal for nearly a week in March. It is reported that it caused commercial losses of up to $ 10 billion per day.

Besides, its damage was so intensive that its whole lower bow needs to be replaced with a new one.

According to the public reports, technical faults or human factors could be the cause of this accident. A thorough and regular inspection of ships is a necessity for the ship to ensure a safe journey.

Three-dimensional scanning can be applied to the inspection of ships with its efficient scanning and high precision. With large-area scanning and fine scanning, it can be used to examine all parts of the ship.

Let’s take ship pipes as an example. These pipes take on complex geometries with different spatial angels and bending angles.

With the pipe measurement module, the KSCAN 3D scanner can quickly obtain the 3D data of the pipe through the high-speed scanning mode and capture the details of the pipe through the ultra-fine scanning mode.

After scanning, the scanned data is compared against the original value through professional data processing software. In this way, technicians can immediately identify whether the pipe meets the criteria and the areas to be repaired.

Summary

Scantech’s 3D scanning technology can also be used in reverse engineering and modification of a damaged hull. Scantech will continue to support customers in the development and design, assembly, inspection, maintenance, repair, and modification of products.

By reducing the time and costs of design and inspection, we devote ourselves to optimizing the overall process of the ship industry.