3D Solutions To Rail Transport

Due to its advantages like high safety, efficiency, capacity and low pollution, rail transport has become an important method for daily travel and cargo movement.

The rapid development of rail transport poses higher requirements for the manufacturing of relevant equipment. 3D scanning starts to play a crucial role in product development and quality control for components and molds. Rail transport components are usually bulky objects with a mass of curved surfaces. Traditional methods require large working spaces and a long period of time to complete measurements with mediocre accuracy. The problem of low-quality, low-efficiency can be perfectly solved by 3D scanning.

Detection of structural castings for train chassis

The structural casting for train chassis to be detected measures about 1,200mm long, 600mm wide and 400mm high, which has a central platform supported by 6 cones. The casting has a medium-to-large size, multiple curved surfaces and angles. The diameters of different cross sections of the 6 cones, the number of degrees of each angle, and the length and width of the central platform should be measured in order to provide data for subsequent processing.

To meet these needs, SCANTECH selects the KSCAN composite 3D scanner to perform the measurement tasks. The KSCAN scanner completes a scanning area as high as 1440 mm * 860 mm per single shot and has a scanning speed of 1,350,000 measurements/second. Ultra high scanning area and speed ensure the scanning rate of medium-to-large sized components, reducing the duration of scanning and data processing to less than half an hour.

Metro train mold detection

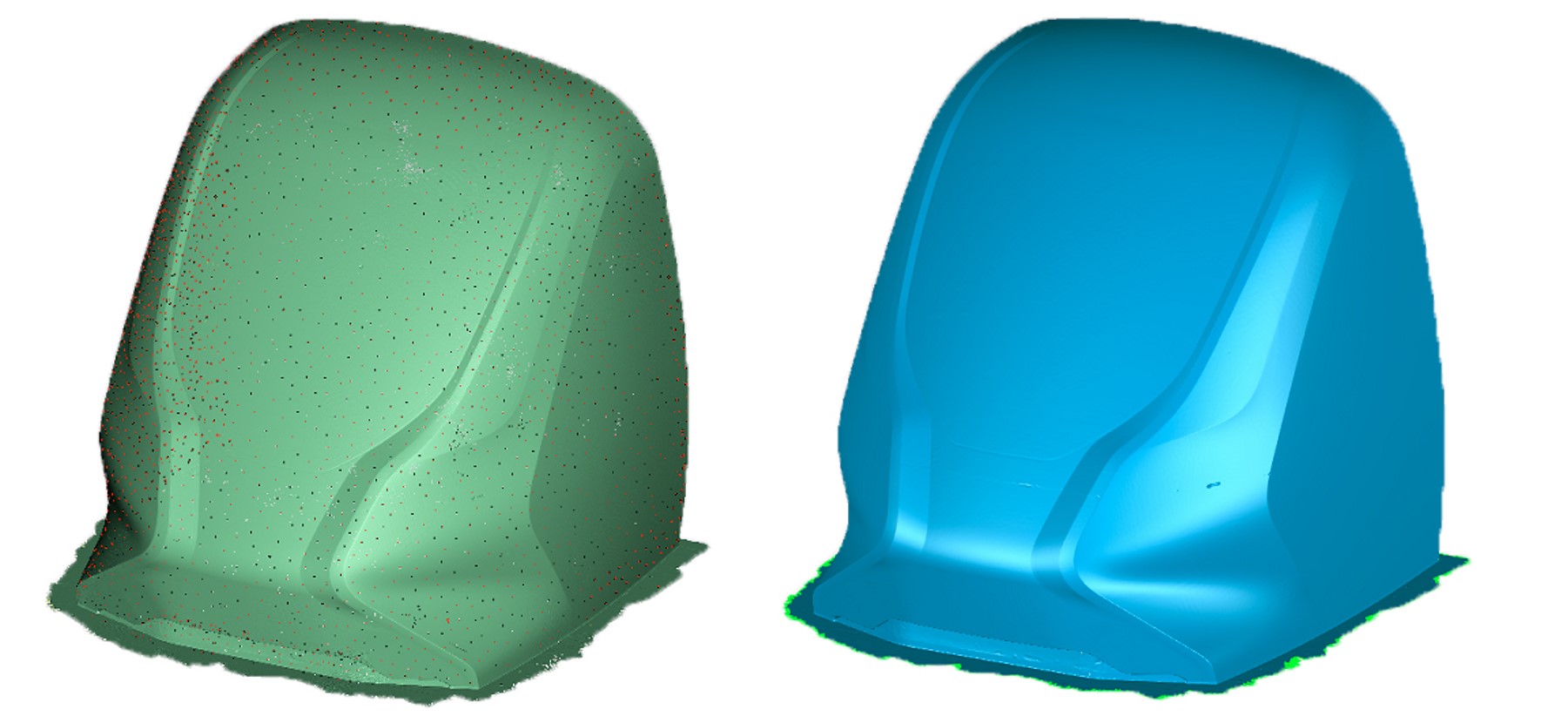

Moldmaking is one of the key procedures in metro train manufacturing. Metro locomotive manufacturing can be largely divided into the following procedures: design mold development manufacturing assembly. Metro train manufacturers need to perform 3D scanning over locomotive mold to achieve 3D measurement data, and then compared the data with original digital analog to calculate potential deviation values and thus increase product accuracy.

Due to the bulkiness of a locomotive mold, it is very difficult to ensure scanning accuracy when using ordinary 3D scanners. To address the problem, SCANTECH offers a 3D solution consisting of a handheld 3D scanner coupled with the MSCAN global photogrammetric measurement system. MSCAN systems are specialized in the high-precision measurement of geometric sizes for large-sized workpieces and manufacturing equipment, which can be coupled with Scantech 3D detection device in operation. The device weighs only 0.58kg, offering great portability and ease of use by just one operator. The MSCAN global photogrammetric measurement system has a super large frame of 9.4m 6.9m and a super large depth of field of 6.5m, delivering a volumetric accuracy of 0.015mm/m. The system can easily cope with the measurement of ultra large-sized components and significantly increase measurement accuracy.

Metro locomotive detection

Compared with molds, the 3D detection of metro locomotives poses more stringent requirements after they are manufactured. Questions like whether the overall error falls within the limit of design, whether the mounting holes of locomotive windows or doors are compliant with standards are closely related to the safety and stable operations of metro trains.

In the same vein, SCANTECH also offers a solution consisting of a handheld 3D scanner and the MSCAN global photogrammetric measurement system. First, the MSCAN gobal photogrammetric measurement system is applied to obtain spacial positioning points of the locomotive. Then, the handheld laser scanner is deployed to obtain 3D data. Finally, the derived 3D data is compared with the digital analogy of the locomotive and the quantity of deformation is calculated for later product improvement.

Today, 3D scanning has been widely used in the quality test of components, parts and molds of metro and conventional trains. Undoubtedly, 3D scanning also plays a crucial role in other aspects of rail transport, such as structural section test of metro tunnels and automatic test of railway tracks. 3D scanning provides accurate, rich data resources for various genres, from deviation correction, virtual assembly to repeatable analysis, traceability, during the development and manufacturing of rail transport.

For more cases about 3D scanning, please read:

Accurate Measurement of Tesla Empowered by KSCAN 3D Scanner

Persistent Improvement in 3D Inspection of Large-sized Object

Paint Protection Film to Build Automobile Data Center by 3D Scanning