DUBLIN–(BUSINESS WIRE)–The “Automotive Mold Market – Global Outlook and Forecast 2019-2024” report has been added to ResearchAndMarkets.com’s offering.

This report mentioned that the “global automotive mold market is expected to grow at a CAGR of over 7% during the forecast period 2018-2024”.

The passenger car segment dominates the automotive mold market for the vehicle type category. The consistent demand for molds and persistent, innovative offerings by automakers is the major driver for the considerable demand for passenger cars.

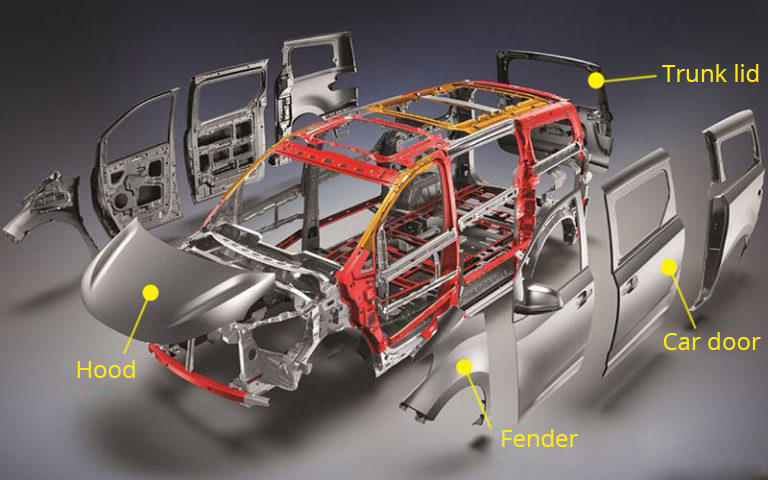

Exterior parts are widely molded worldwide in the automotive market as they are crucial for the vehicle’s outer body. The growing innovation is encouraging vendors to enhance die-casting mold offerings.

Innovation from 3D scanning and automotive manufacturing

Apparently, automotive mold carries a big weight for the vehicle industry. The automobile cover mold has a more prominent position since it directly affects the car structure and the possibility of successfully assembling. It is conceivable how precise the automobile cover mold will be.

Technological upgrades and enhanced production methodology remain highly crucial in the market. 3D scanning is a non-contact and non-destructive technology that digitally captures the shape of the objects and collect data on its shape.

It has a wide range of applications no matter in industrial areas or our daily life. But how does 3D scanning help automakers stand out in the highly competitive automotive manufacturing market?

Handheld 3D scanner has been favored by more and more enterprises in recent years due to the following features:

- High-precision

- Time-saving & labor-effective

- Easy to operate

However, constrained by its working principles, handheld 3D scanner can’t overcome some defects when confronting with large-scale objects

- Generate cumulative errors

- Difficult to get small details

Need extra measuring device (or something that has photogrammetry system) to improve scanning accuracy, which will increase the budget and be time-consuming during the operation.

ScanTech 3D Solution

Market-drive is to help customers easily cope with what they worry about.

A versatile 3D scanner simultaneously has the functions of normal handheld 3D scanners and photogrammetry system. Our KSCAN 3D scanner, a professional metrology-grade 3D scanner with a wide range of applications, forms its extraordinary strengths compared with normal handheld 3D scanners:

- Built-in photogrammetry system: bring more convenience for scanning large workpieces; improve volumetric accuracy up to 0.035 mm/m.

- Flexible measuring range: excellent performance on scanning large and small objects

- 650,000 measurement rate under red laser scanning mode

- Resolution up to 10μm