Application of TrackScan 3D Scanning System In The Manufacturing of Large Scale High Temperature Forging Molds

In recent years, with the continuous improvement of mold manufacturers’ requirements for on-site quality control, process optimization, and data storage, measurement equipment is also required to provide more timely, accurate, and intuitive feedback modes. The customer in this case is a mold manufacturer who desires to strengthen the inspection of the machining allowance of the mold’s curved surface through 3D scanning equipment. As the mold weighs 5 tons and is not easy to move, the inspection work needs to be carried out in the daily production process. The customer used traditional measurement methods which are quite inefficient due to the large size and area.

Scanning requirements and difficulties

- High efficiency requirement: to complete scan detection and comparison within 15 minutes

- Large size: the object size is 2.1m*1.6m*0.7m

- The requirement of precision is 0.05mm; mold cavity contains many characteristics, deep holes and grooves; the machined surface is very reflective.

- The workshop environment is harsh, dusty with large temperature difference.

The solution of SCANTECH 3D

According to customer’s requirement, SCANTECH provides the customer with a set of flexible and portable 3D measurement solutions suitable for the workshop environment: use TrackScan-P42 tracking 3D scanner to scan, and then compare the scanned data with the digital model to generate a color mapping to show whether there is the deviation of the mold surface, and the customer can quickly carry out the mold repair accordingly based on the test report.

SCANTECH 3D Scanning Advantages

- High inspection efficiency

- The whole process only takes 10 minutes, including 5 minutes for scanning and 5 minutes for reporting.

- It can be operated in workshops and in poor environmental conditions.

- It is not sensitive to changes in the workshop environment (vibration, temperature, humidity, lighting), and can easily obtain 3D data of reflective objects, especially suitable for products that cannot be moved.

- Flexible and convenient operation

- Hand-held operation; can be taken to any place in the workshop; no need to paste markers; instantly scan; significantly improve work efficiency; reduce labor and material costs.

- Results are obtained faster, accurate and intuitive

- It can automatically generate a measurement report with CAD color mapping in 5 minutes, with the accuracy up to 0.025mm.

Scan Data and Processing Results

Based on intelligent optical tracking measurement technology, the TrackScan 3D scanning system does not need to paste markers, and the scanning speed can reach 1,900,000 measurements/sec. It can quickly complete full-scale high-precision scanning.

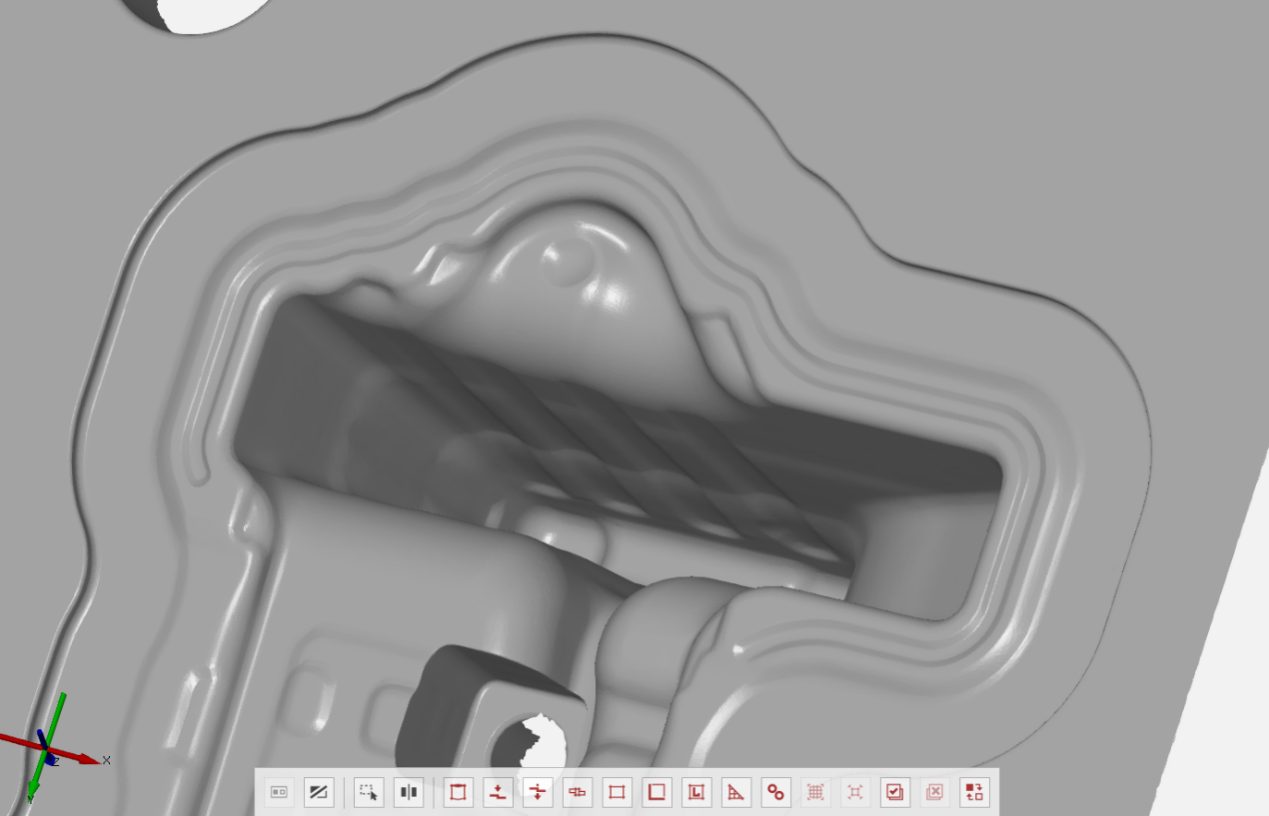

Data capture and processing, as illustrated in following figures. The deviation of the mold surface can be seen intuitively through color mapping.

The site of scanning mold

Details of deep holes

Mold inspection results

Brief summary

TrackScan 3D scanning system has gradually become a very advantageous auxiliary tool in mold production and processing with its superior workshop site adaptability, measurement data reliability, and completeness of software functions, bringing new solutions for mold manufacturers to shorten the production cycle and reduce costs.