KSCAN Helps Chile Hydropower Turbine Renewal Design

Hydropower is a very important energy industry and also an important application industry for 3D digital technology. In this issue, we will share a turbine reverse transformation case from the Chilean company GEOCOM, our overseas agent partner, and see how the KSCAN composite 3D scanner meets the needs of the renewal design of power generation turbines.

Background

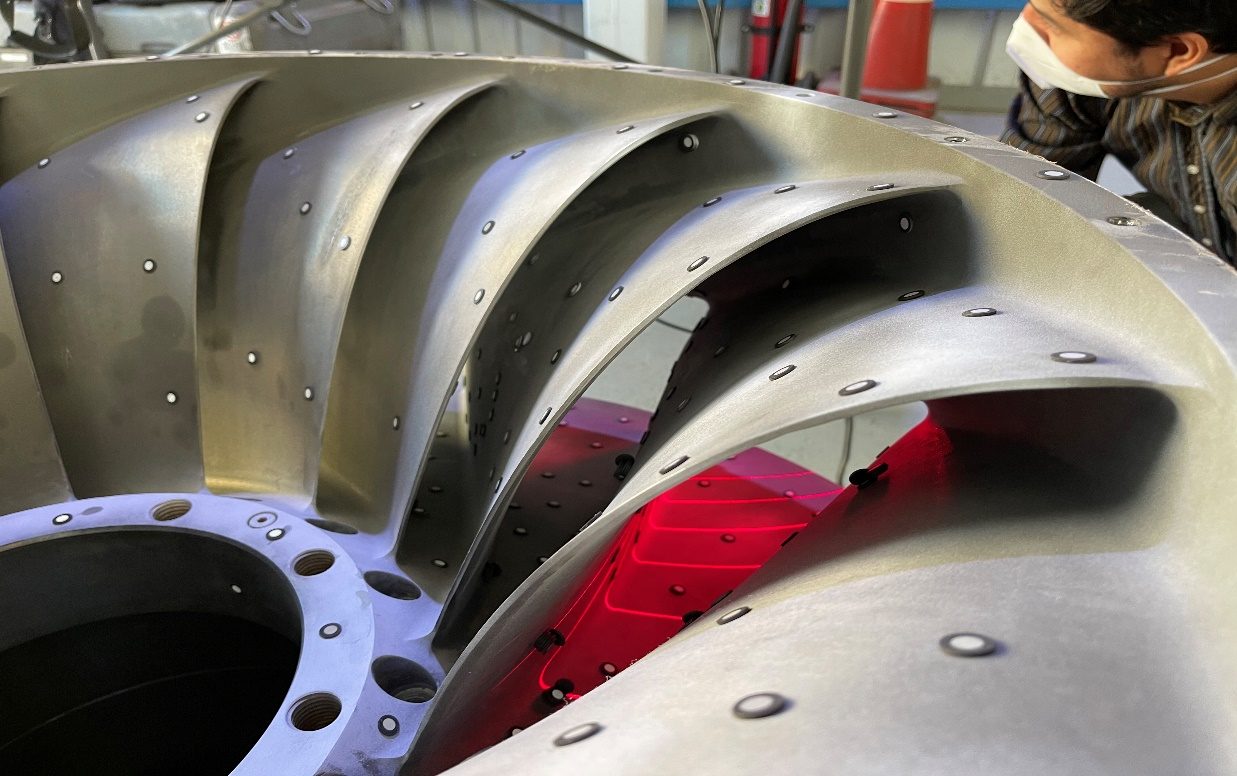

In the process of hydroelectric power generation, due to the constant impact of the torrent of water with moving parts, the impeller blades and all components subject to such stress suffer a lot of wear and tear, and they need to be repaired and updated regularly.

The main problem for customers is that they do not have manufacturing drawings for these components. Due to the compact and complex structure of the turbine casing, the impeller blades are spatially curved, highly twisted and have elevation angles.

It is difficult to achieve the expected results if using traditional measurement methods such as callipers or micrometres. Also, there are problems such as large human measurement errors and low efficiency.

SCANTECH 3D Solution

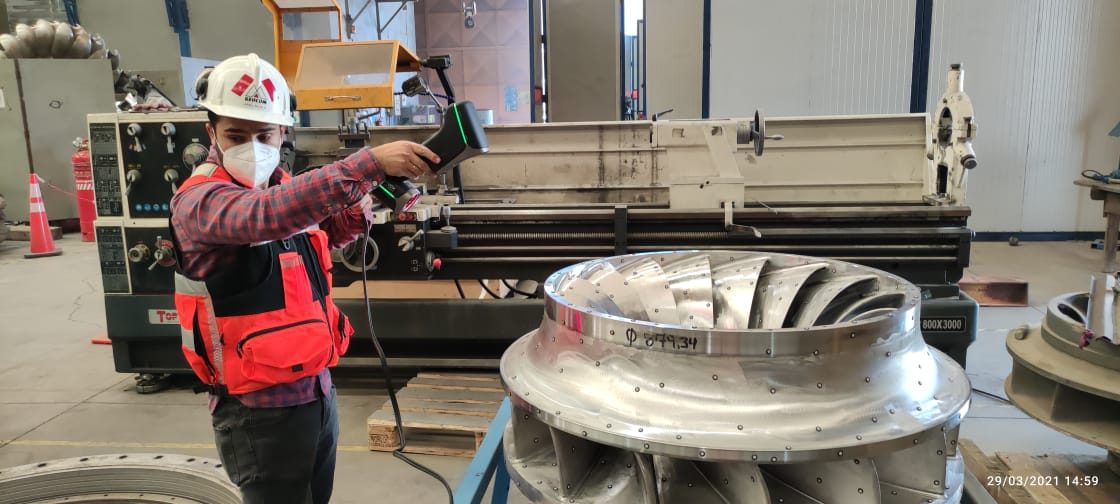

Use the KSCAN composite 3D scanner to obtain the point cloud data of the existing turbine, and then cooperate with the Design X reverse software to process the scanned data, including patch fitting, section creation, curve extraction, etc., and finally get the CAD model. In addition, it is possible to carry out innovative design and optimization design on the existing basis to develop more suitable products.

Scan data and process results

-

Scanning

-

Processing optimized scan results

-

Reverse engineering to obtain a CAD model

-

Ultra-full data

With the help of advanced laser scanning technology, KSCAN can measure almost any part without being restricted by size, shape, material, surface complexity, and supports contact measurement to make up for the deficiencies of traditional equipment in reference hole measurement, hidden point measurement, feature measurement, etc. Place.

-

Ultra-high precision

KSCAN’s world’s first red and blue dual-colour laser technology and the world’s first patented built-in photogrammetry technology, the highest accuracy can reach 0.020mm, the highest volume accuracy can reach 0.010mm+0.015mm/m.

-

Superfast efficiency

The scanning rate is as high as 1,650,000 measurements/second, and the whole process takes less than 1 hour. The generated results can be seamlessly integrated into your preferred reverse engineering and CAD software.

Summary

The KSCAN composite 3D scanner greatly optimizes the turbine digital reverse workflow with its unparalleled scanning speed, accuracy, and area, avoids the disadvantages of traditional methods, and realizes the redesign of the turbine, which is the digital reverse engineering of complex products. The design provides a practical solution.