Scantech 3D Model in Machinery Manufacturing Industry

3D scanning allows for the precise capturing of physical objects and components, enabling the creation of digital 3D models that serve as the foundation for product design and prototyping in the machinery manufacturing industry. These 3D models streamline the development and testing of machinery, reducing both time and cost. Additionally, 3D scanning facilitates quality control by comparing scanned parts to CAD models, ensuring that manufactured components meet stringent standards.

The Scantech KSCAN-Magic 3D scanner is a valuable tool for capturing detailed 3D data of large heavy-duty castings for a wide range of industrial applications.

A 3D scan of a blade is helpful to capture precise information about the blade's geometry, such as its dimensions, curvature, and surface quality.

The Scantech KSCAN-Magic 3D scanner can create a 3D model of an impeller with helix structure, capturing its geometry, blade angles, and tolerances with high precision and detail.

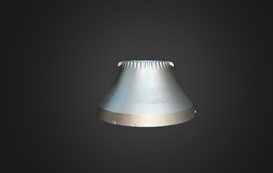

Designing a 3D model of an air-conditioning compressor component with the Scantech 3D scanner provides numerous advantages.

The Scantech 3D scanner optimizes crusher wear parts by enabling precise wear profiling, efficient manufacturing, and performance simulations.

Request a demo

As you explore our 3D models, we encourage you to request a demo, allowing you to see the world through a new dimension. Your inquiries are our priority, and we're excited to provide you with a firsthand experience of our cutting-edge 3D technology.

Book A Demo