Detail Scanning on Die Casting with 10μm Resolution

There are many important factors to strengthen economic development. Technology-driven contribute a lot to human beings.

Machinery manufacturing also takes its place in economic growth, and it reflects a country’s comprehensive powder. Aluminum die-casting is common in machinery manufacturing, and it is widely also applied to many fields like automobiles, electronics, and home appliances.

What does the manufacturer need?

It is likely to get deformation for aluminum die-casting during production due to such factors: unsatisfactory structure, inadequate rigidity, improper gate placement, and rough surface, which will seriously affect quality control and work efficiency.

High-precision aluminum die-casting usually has many features as well as tiny details. Therefore, the manufacturer needs to know the accurate deviation values and revise the errors timely. This will have very high requirements for a 3D scanner.

ScanTech 3D solution

This aluminum die-casting is the size in 200mm*200mm and is scanned by our latest innovation KSCAN 3D scanner.

This composite 3D scanner integrates the following advantages:

● Global innovation (red and blue laser scan mode) as our other handheld 3D laser scanners.

● Built-in photogrammetry brings more convenience to scanning large workpieces with 0.035mm/m volumetric accuracy

● 10μm resolution under ultra-precise scanning Mode B

● 0.02mm accuracy to get accurate 3D data

● Ultra-high work efficiency: 650,000 measurements/s

● Equipped with portable CMM

● Unlimited measuring range

● Wide scan area and applications

Scanning Process

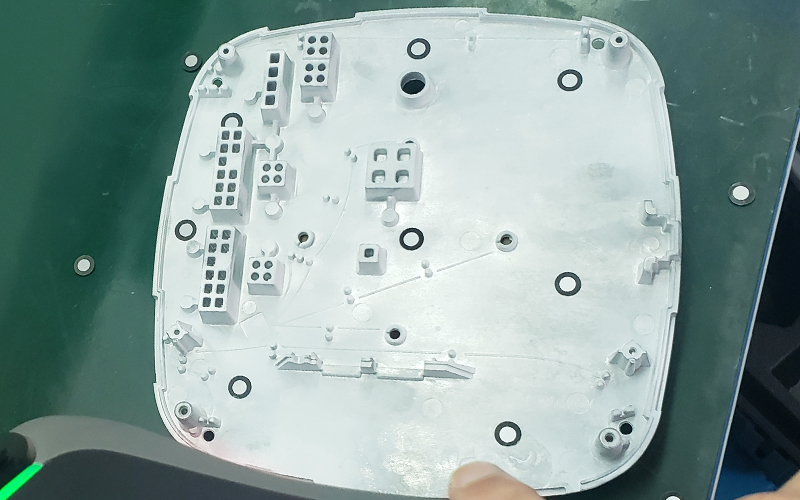

Step 1: attaching markers

(Only need half markers compared with normal handheld 3D scanners)

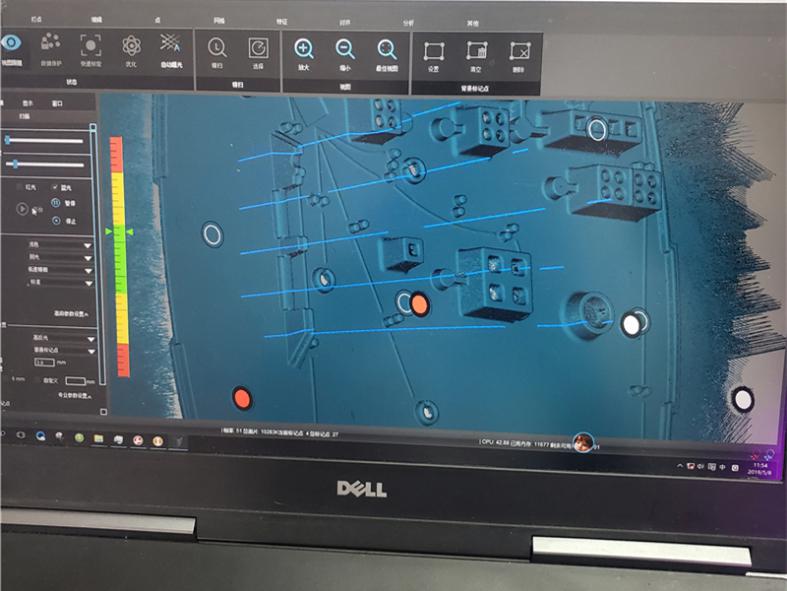

Step 2: Scanning both sides of aluminum die-casting under blue laser mode

Real-time visualization

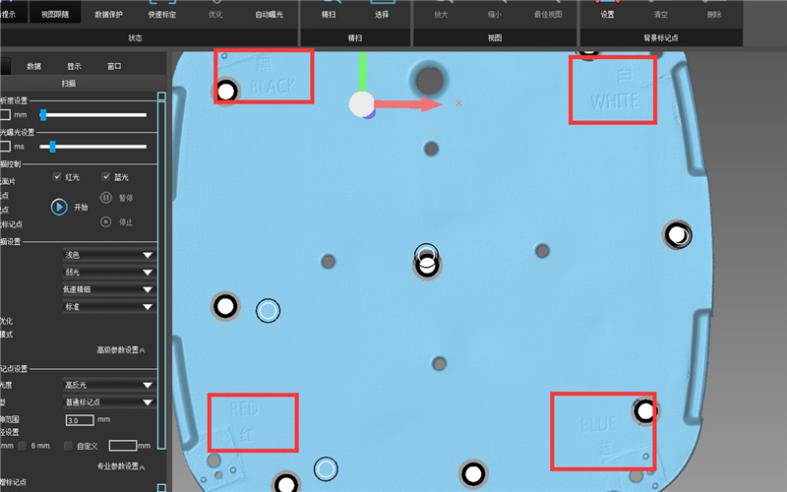

Step 3: Combine with 3D software ScanViewer to quickly obtain the full 3D point cloud data under background mode.

Point Data of Front Side

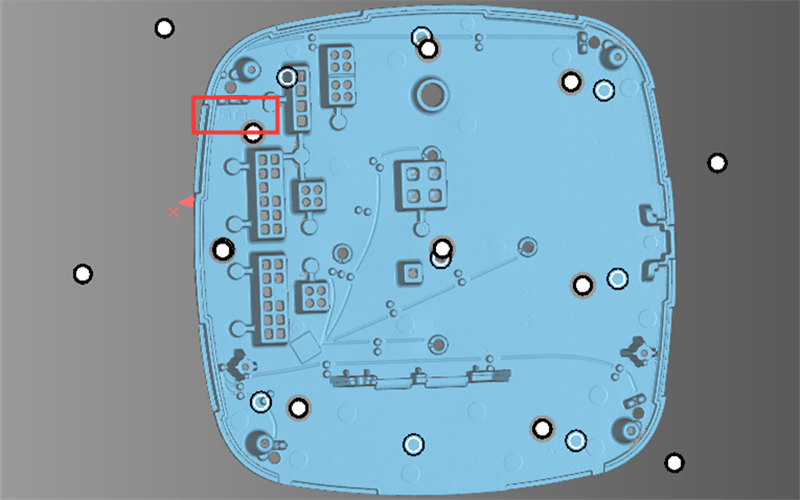

Point Data of Back Side

Small Characters

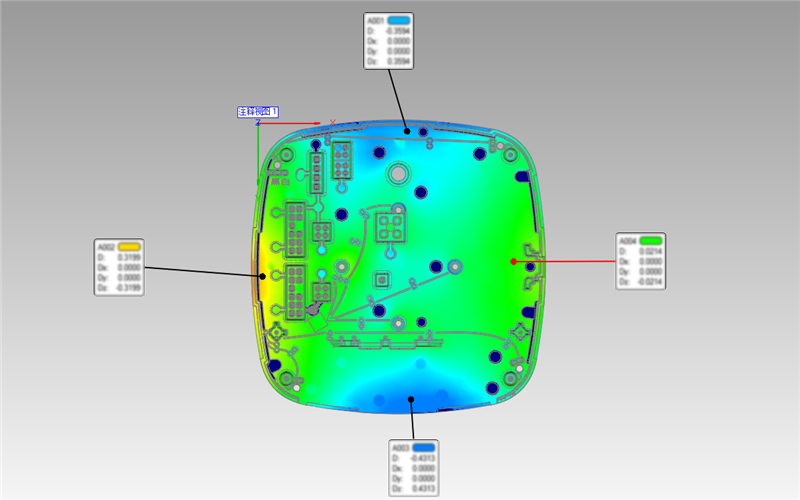

Step 4. Generate deviation values and color map

Color Map of Front Side

Color Map of Back Side

Time Cost

Attaching markers:1 minute

3D scanning: 10 minutes

Generating scanning report: 5 minutes

The versatile KSCAN 3D scanner greatly cuts down the working time with very few markers. It guarantees efficient and accurate scanning so that the manufacturer gets the precise 3D data of aluminum die-casting in a very short time.

Our intelligent 3D software ScanViewer is used for contrast detection and fast calculating deviation values. This gives support for post-process and improves the work efficiency of manufacturers.

For more information about KSCAN, please read the following articles: