AXE 3D Scanner–10 Minutes to Scan Sheet Metal

Auto body is mainly made by stamping and welding of sheet steel, and it is also the carriers of engine and chassis. Therefore, the quality control of sheet metal must be guaranteed.

What does customer need?

Auto body installation will use curve sheet metal, however, the sheet steel is too thin and easy to rebound, so the installation process will be affected.

Quickly obtaining the deviations between the sheet metal and CAD drawing is urgent for manufacturers.

What is the traditional measurement?

Traditional measurement is to place the sheet metal on the inspection tool and use the plug gauge for qualitative analysis.

- Fail to get deviations of the sheet metal

- Can’t perform deformation analysis

- Only detect the deviations of set positions

This way won’t help manufacturers make a reasonable adjustment for unqualified sheet metal, and also decreases work efficiency.

ScanTech 3D solution

Global initiative AXE 3D laser scanner overcomes the disadvantage of traditional measurement. It is characterized by several factors:

- Doubles scan area & faster measuring

- Half markers & time-saving

- High precision, flexibility & portability

- Overturn the measurement way for large volume

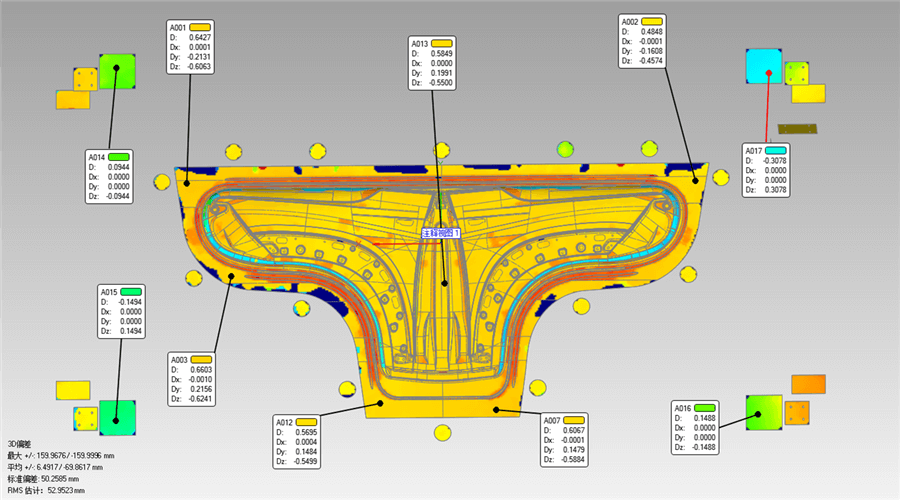

It can capture 3D point cloud data of steel metal to form stl data, and calculates deviations by comparing with original CAD data. Moreover, there will be a deformation analysis and detection report.

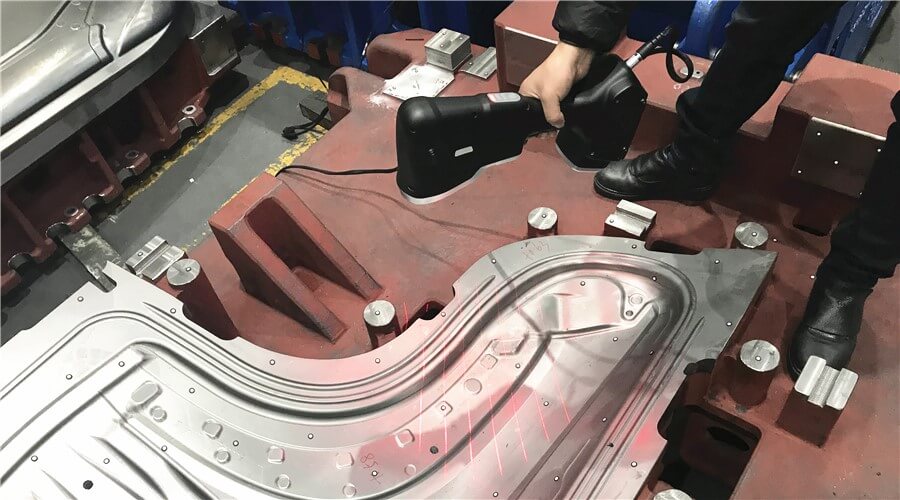

Time cost & Scanning process

-

Attaching markers: 3 minutes

-

Scanning: 5 minutes

-

Detection report: 3 minutes

stl 3D data

Original CAD data

Contrast detection

ScanTech AXE global 3D scanner combines the functions of normal handheld 3D scanner, greatly reducing the cost of device, time and labor. It provides accurate deviation values of steel metal for manufacturers so that the production process could be smoother and the quality can also be under control.

AXE 3D scanner is specially designed for scanning large volumes, please read this application for any interest.