How to solve the problem of car seat design with 3D scanning?

Seat design is the first step of the car design. Due to many considerations, the design is very complicated, so the design cycle of a seat usually takes more than 2 years. In order to shorten the design cycle, the domestic design is usually reversed based on the existing seat shape. As a fast and efficient way to acquire 3D data, handheld 3D scanners are critical to the impact of car seat design efficiency.

Science time

How important is seat design to car design?

Designing the seat is the first step in the design of the car. The designer considers the sitting position of the members in the car firstly. The position, shape and adjustable angle of the seat are designed according to the H point of the human body, so that the steering wheel can be finally determined, as well as the position of the pedal, center console, door and other components.

Ergonomic considerations

How hard is the R&D of the car seat?

Seats are used very frequently, so each part must be designed with comfort, safety and durability, as well as lightweight, but the factors are extremely complex, so the seat structure R&D cycle is very Long (about 2 years or so). Seat design requires both data and development experience, as well as professional laboratory verification facilities and technology. At present, it is very difficult for domestic automobile manufacturers to independently R&D a Seat.

Does the design and manufacture of car seats in China require 3d measurement?

Of course, since the domestic car manufacturer usually reverses the existing seat and then remodels it, the three-dimensional measurement data of the seat is crucial to the redesign process.

What is the 3D measurement method of car seats in the past?

The original 3d measurement of the seat mainly used manual measurement and three-coordinate measurement. Because the skeleton structure of the car seat is complex and the seat material is soft, the traditional contact measurement method is very limited in terms of efficiency and data integrity. The cost of 3D inspection is very high.

What are the advantages of handheld 3D scanner measurement?

1, measurement speed;

2, data integrity;

3, data accuracy;

4, operational flexibility;

5, reduce costs greatly.

SHOW TIME

The customer: Car seat manufacturer

Scanning object: Seat frame

Scanning device: PRINCE775 handheld 3D scanner

Aim: Used for product reverse design and improvement

Firstly, customers need to acquire existing seat data quickly, and then design and improve the structure of the seat based on existing data.

The PRINCE series handheld 3d scanners perfectly meet customer needs in the following four aspects:

1.The scanning speed of 480,000 measurement/second can quickly obtain the three-dimensional data of the seat in all directions.

2.Blue laser ultra-high detail 3D data acquisition capability

3.Non-contact measurement method, no need to spray powder on the surface of the workpiece.

4.The device is less than one kilogram, deft and portable, easy to operate.

The solution

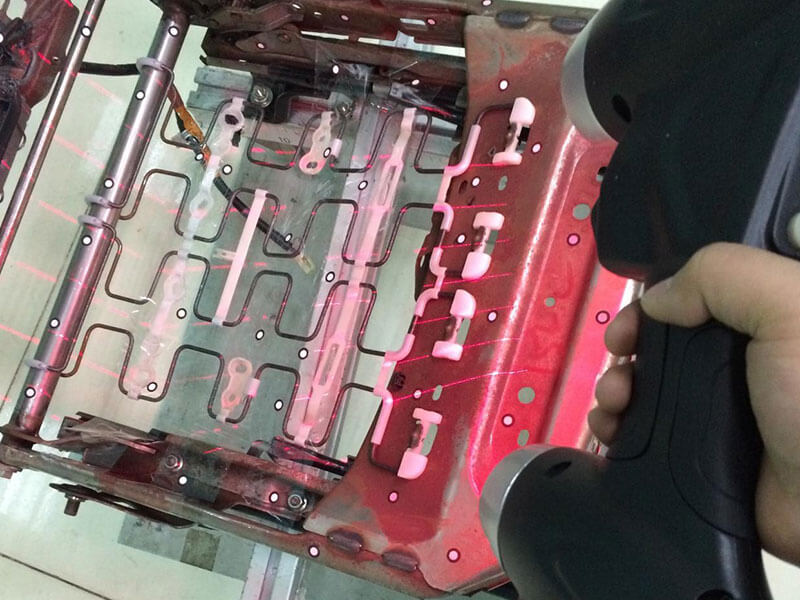

Scantech providing customers with PRINCE775 for 3D scanning. After marking position mark point quickly on the seat surface, real-time scanning imaging with PRINCE red model to obtain point cloud data on the seat surface. For partial details, use blue mode to achieve high detail, and finally the 3D data of the seat is imported into the reverse software for redesign and improvement.

Scanning object

Device & Model: PRINCE775 handheld 3D scanner

3D inspection process and results

3D scanning process

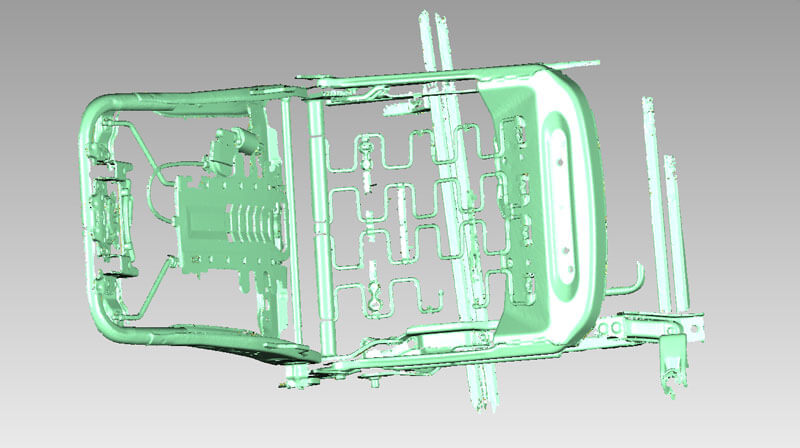

3D point cloud data

3D scanning working time

It takes 15 minutes to mark points.

It takes 10 minutes to scan.

It takes 3 minutes to inspect and report.

28 minutes in total.

PRINCE series

Three-dimensional reconstruction artifacts that can scan all sizes.

The PRINCE 775 3D scanner can quickly acquire 3D data of objects, at the same time, its unique Blue mode can meet the detail scanning requirements of various parts. The powerful functions of PRINCE provide a fairly accurate and reliable design for the reverse design and improvement of car seats, which greatly shortens the time for reverse modeling of the automobile, and is suitable for the reverse modeling of various components of the automobile, which brings great convenience to the automobile manufacturing industry.