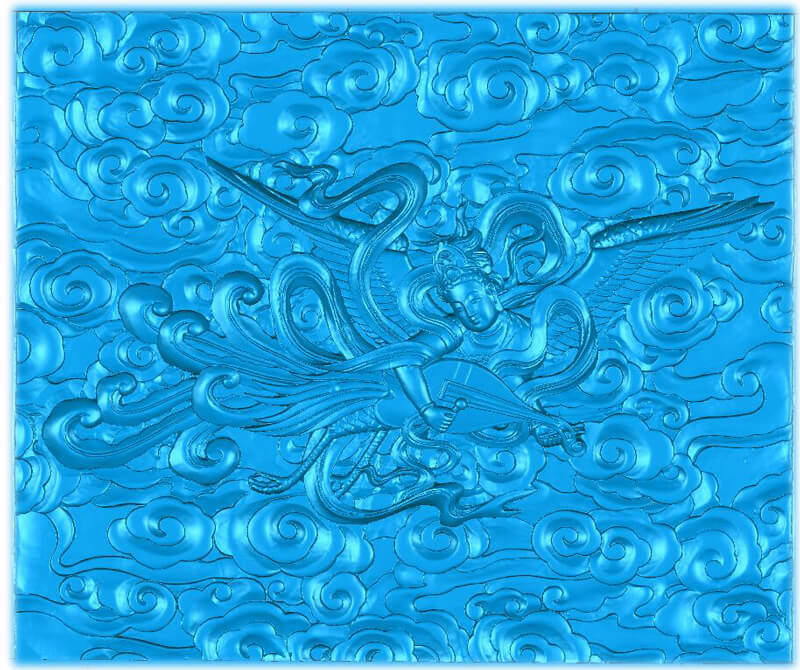

Summary: The original dual-mode mode of PRINCE 3D scanner helps the woodcarving industry to quickly and accurately obtain the 3D data model of the woodcarving surface, greatly reducing the modeling cycle and labor cost of the woodcarving industry. The obtained 3D data model is more accurate than manual engraving and can be widely used in the fields of 3D engraving, 3D printing, etc., the three-dimensional scanning technology is used to realize the revolution in the wood carving industry. The following is a 3D scanning application case for customers in the woodcarving industry.

3D scanner and woodcarving

With the popularity of 3D engraving equipment in the woodcarving industry, a CNC stereo engraving machine can simultaneously produce several three-dimensional or flat wood carving crafts, greatly simplifying the engraving cycle and difficulty of the traditional wood carving industry. The premise of 3D engraving work is to have a complete woodcarving 3D model, so that programming can be added to achieve intelligent manufacturing or 3D printing. However, the texture of woodcarving is intricate and detailed, traditional 3D modeling has two major obstacles:

① Long modeling cycle and high labor costs

② It is difficult for a modeler to accurately model wood carvings which is extremely complex

Therefore, a simple, fast and efficient 3d modeling method plays a vital role in the wood carving industry.

The appearance of PRINCE with two-color laser handheld 3D scanner is the biggest gospel in the wood carving industry. Next, let’s take a look at what kind of sparks might collide between hand-held 3D scanners and wood carvings