Tracking 3D Scanner

Intelligent 3D Tracking without Attaching Markers

Experience cutting-edge 3D solutions with the TrackScan series 3D scanners, revolutionizing the acquisition of accurate 3D data without the need for markers. This professional 3D optical measurement system boasts a super-fast scanning rate, setting a new standard in efficiency. Crafted with aerospace-grade carbon fiber materials, it ensures a robust and durable 3D measurement experience.

The applications of this advanced 3D scanner are vast, spanning quality control, product development, reverse engineering, 3D printing, and more. Moreover, the TrackScan series is designed to seamlessly integrate with an automated 3D system, eliminating the need for human interference in the 3D inspection process. Trust in the innovation and reliability of TrackScan series 3D scanners for unparalleled precision in your 3D measurements.

TrackProbe 3D Probing System

The TrackProbe 3D probing system is impressively accurate, portable, and user-friendly, making it easy to ensure high-quality measurements in large measurement volumes, at long distances, and in harsh conditions. It is suitable for various tasks on the shop floor, such as fixture adjustment, benchmark marking, and more.

TrackScan-Sharp 3D System

TrackScan-Sharp brings optical measurement to a whole new level by offering a tracking distance of up to 6 meters, a volumetric range of 49m³, and volumetric accuracy of up to 0.049mm (10.4m³).

TrackScan-P 3D System

TrackScan-P series 3D system delivers 2,600,000 measurements/s and reaches accuracy of 0.025 mm. This 3D system is ideal for medium to large-sized workpieces without attaching markers.

What is the best 3D scanner for your demands?

SCANTECH 3D is a global leader in 3D scanning technology, providing non-contact measurement technology of the optical scanners coupled with precision measurement within product cycle times. Discover more Scantech 3D metrology solutions for you.

If you need to scan large-scale parts such as cars, boats, wind power hubs with high precision and efficiency, you might be interested in our TrackScan optical 3D measurement system. This industrial and target-free 3D laser scanner can capture the geometry and dimension of objects with ease.

The TrackScan system can work in various environments, such as indoors, outdoors, bright, or dark. To learn more about the TrackScan, please check out the specifications below:

TrackScan-Sharp 3D System |

|

|---|---|

| Accuracy | Up to 0.025 mm (0.0009 in) |

| Scanning rate up to | 2,600,000 measurements/s |

| Scanning area up to | 500 mm × 600 mm (19.7 in × 23.6 in) |

| Marker | Without markers |

| Resolution up to | 0.020 mm (0.0008 in) |

Cooperate with top-rate 3D scanner provider

Enable you to measure and scan everything

Scantech 3D Optical Measurement System Solution Designed for Unique Needs of Different Industries

Find out how our optical 3d measurement scanner helps.

With TrackScan-Sharp industrial optical 3d metrology measurement system, you can scan the entire airplane and its complex parts, such as the engine inlet lips and wings to obtain accurate measurement results. It is capable of scanning large objects easily thanks to its large tracking volume. It allows you to inspect airplanes manufactured or detect damages after long-term use.

The TrackScan accurate 3D scanner can scan large objects efficiently, thanks to its large scanning area and dynamic tracking. It enables you to scan the whole hydro turbine to inspect blade geometries, distance, and angular position of individual blades and detect any defects or damages. High-tech 3D scanning hydro turbine can help to optimize its performance and efficiency.

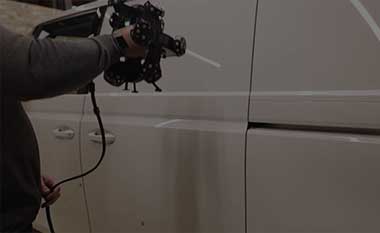

How to 3D scan a car with ease and accuracy? Using the TrackScan optical 3D measurement system, you can scan the whole vehicle, including side mirror and reflective white car body. You can also use a special shadowless-light-module to scan the holes. This fast and accurate system can capture the shape and size of the car and display 3D data captured in real time.

3D Optical Measurement System for Power Plant and Manufacturing

3D Scanning for Power Plant

Scantech 3D optical measurement systems are suitable for product development, inspection, and quality control of energy systems’ parts and components such as turbines, blades, and hubs, especially those with complex free-form surfaces. Efficient and high-resolution 3D scanners can measure the geometry, defects, and wear of these parts quickly and accurately, without damaging them. By enhancing the performance of energy equipment, this can lower the costs and increase the benefits.

Portable 3D scanners can also be used for prototyping and product development of power systems. TrackScan 3D scanner can capture the 3D data of existing products or prototypes and convert them into digital models that can be modified, improved, or customized. This can save time and costs, enhance product design, and increase competitiveness of the hydro and wind power plants.

Scantech 3D scanner company offers non-destructive inspection scanners for quality control. TrackScan series 3D laser scanner are used to quickly obtain the 3D data of complex curved surfaces, including coaxiality and cylindricity of parts. With precise 3D data captured, users can analyze the GD&T of parts. This portable 3D scanner can be a new method for inspecting wind and hydro power plants.

Our metrology 3D scanners can speed up the maintenance and upgrade of power components. These mobile scanning devices allow manufacturers to inspect defective areas or components that need to be replaced. Therefore, regular detection and maintenance can be conducted efficiently to ensure all these parts function well. The 3D data captured can also show the real conditions of parts and guide further upgrading.

3D Scanning for Manufacturing Industry

Scantech’s 3D tracking scanners can be used in manufacturing industry for various purposes from industrial design, quality inspection, to maintenance. It can help create and optimize products, such as tractor chassis, and excavator arms and measure accuracy and performance of parts, including gears, couplings and welds. With our efficient 3D measurement tools, you can inspect the wear and tear of mechanical products and assist in repairing them.

TrackScan optical 3D measurement system supports the high-accuracy and high-resolution data capture of objects. It can measure the deviation of points, lines, and planes from the design specifications or the reference model. Without moving the large-scale parts, it can 3D scan complex parts with curved surfaces or freeform shapes. TrackScan 3D scanning machine can also generate intuitive and easy-to-read inspection reports with full-field data.

By using Scantech optical 3D scanners, the workflow of identifying machining allowances is optimized. TrackScan can compare the design part and the casting blank, and create a map of the excess material to plan and optimize the machining process. With optical and non-contact measurements, they can scan the workpiece at different stages and check for any errors or defects, and also measure the final product’s accuracy and quality.

TrackScan 3D scanning device can create high-precision digital 3D models of physical objects by capturing their surface data. Combined with 3D product design software, these 3D models can help to improve or optimize existing parts, saving time and costs in design and manufacturing. During the process of design, manufacturers and designers can scan parts to test ideas and refine design.

Various 3D scanning solutions for your 3D measurement needs

With Scantech's cutting-edge 3D scanning technology,

you can trust that you are using a reliable and effective 3D scanning solution that delivers high-quality results.