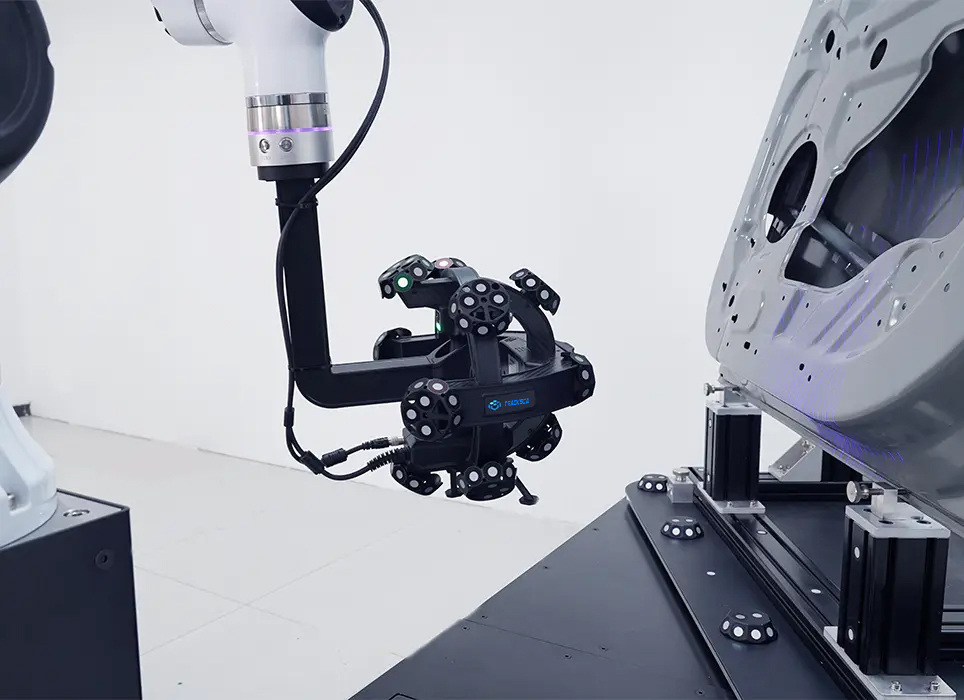

AM-CELL C200 Optical Automated 3D Measurement System

AM-CELL C200 is the all-in-one optical automated 3D measurement system designed for measuring medium-sized parts, taking measurements to the next level. Its modular design allows for flexible layouts and speedy assembly. The system, which can be used without a physical fender, is crafted with an active safety system to avoid safety hazards. It is safe to work directly alongside the operators, suiting well for measurements on the shop floor, in CMM rooms and in educational settings. It offers an automated measurement solution for full life-cycle quality control, giving companies the possibility to increase automation, enhance intelligent manufacturing and upgrade the business.

Efficient and Easy to Operate

Flexible Layouts

Active Safety System

Vast Applications

Lightweight Standardized Product

AM-CELL C200, which is 70% lighter and 60% smaller than its predecessor, is a standardized 3D solution to measure parts for product development and inspection. Its components can be integrated to form the final system easily within 2 days by one operator.

This plug-and-play solution supports labor-free automated measurement and manual robot teaching for quick path planning, which lowers the threshold for professional operations.

Modular Design and Flexible Deployment

Thanks to its modular functional design and small footprint, C200 can be deployed in L-shaped, I-shaped, T-shaped, and separate layouts to fit in various working areas. Its standard interfaces can be connected with different external devices to enable flexible measurements. Its cobot can work with multiple positioners so that operators can change the part on one positioner while the others are working. Therefore, manufacturers can minimize downtime, significantly increasing measurement efficiency.

Innovation to Keep You Safe

The system is crafted with an active safety system. Its robot and turntables are equipped with servo-mechanists with force feedback to avoid safety hazards. There is no need for a physical fencer as it comes with a ten-grade collision detection. Therefore, human operators and the measurement system can share the workplace without compromising safety.

Intelligent 3D Optical Measurement

C200, compatible with Scantech’s TrackScan-P series optical tracking 3D systems, can automatically measure parts without sticking targets. Thanks to its enhanced stability, users can measure hundreds of parts efficiently and stably with reliable and repeatable results.

C200 allows users to inspect edges automatically and its sophisticated gray value measurement ensures precise results. Users can obtain accurate 3D data of closed features such as holes, slots, and rectangles of stamping parts and machined parts on the site.

- Accuracy of up to 0.025 mm

- Measurement rate of up to 2,600,000 mps

Vast Applications Deliver New Experiences

Maximum Object Size: D=Ф1500mm

Object Payload: 200 KG (medium-sized parts)

Power Supply: Main electricity

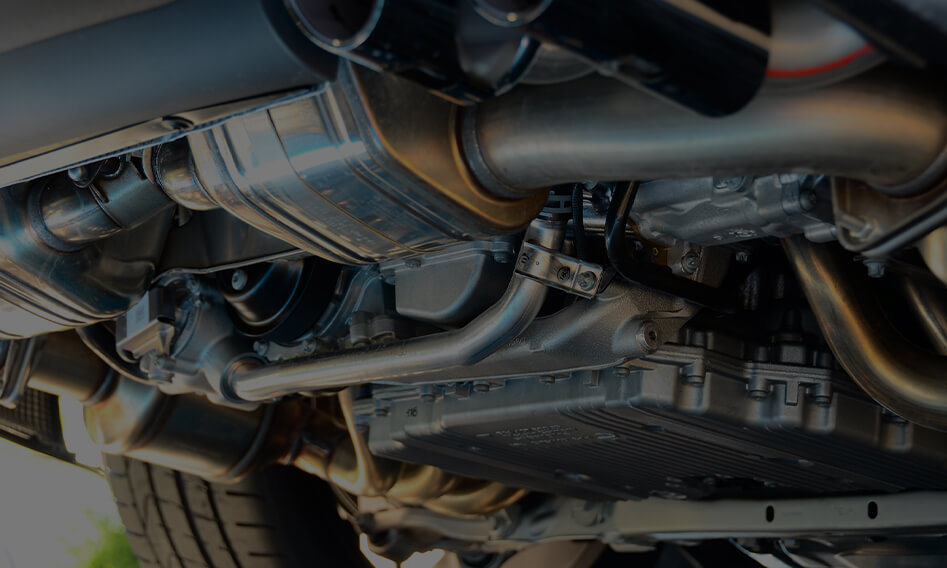

Shop Floor: The measurement cell allows for on-site measurement on the shop floor regardless of lighting and temperature variations. It can measure parts precisely under harsh conditions on the shop floor.

CMM Room: The system can safely and steadily run without special requirements for settings. Physical fencer is optional depending on the requirements of the users.

Educational Settings: With multiple programming methods, teachers and even students without much expertise can learn how to operate the measurement system safely in a short timeframe. It shows our commitment to creating a talent cultivation ecosystem in the way of industry-university-research integration.

Shop Floor

CMM Room

Educational Settings

Information-driven Quality Control

C200 can work with different MES systems and various automated quality control software used throughout industry production. With a one-button-start, users can invoke templates, calculate data, generate inspection reports, and analyze the statistics to gain insights that can boost production efficiency and ensure precise quality control.

- For R&D: C200 features a measurement rate 5 times faster than that of traditional CMM, which is essential to accelerate the research and development, reduce the time of ramp up and speed up the time-to-market of new products.

- For Manufacturing: It supports single-part inspection, multiple-part inspection and trend analysis of batch inspection. This way, users can monitor the evolution of batches, forecast the trend of defective products, reduce the rejection rate, and ensure the stability of manufacturing.

Technical Specifications

Ready To Get Started?

Rebuild our 3D world with the most advanced 3D scanning system available.

Request A DemoWhat’s the best 3D solution for your business?

Boost your business with 3D digitization technology.

Ask An Expert BrochureHigh-tech 3D Scanners

Scantech’s handheld 3D scanners power the 3D scanning services. These instruments can obtain precise point clouds, which can be triangulated into a polygon mesh or STL file.

Due to their high precision, versatility, and portability, they can fulfill various metrology-grade 3D scanning projects.