Photogrammetry System

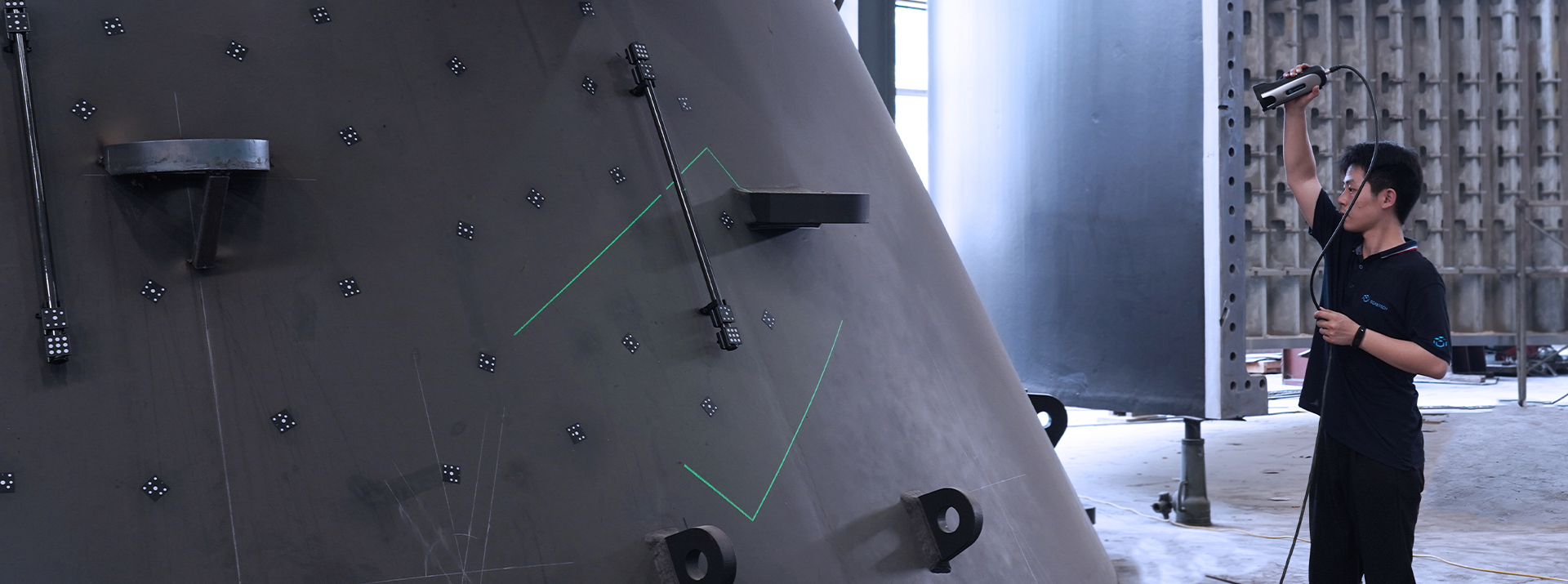

Integrating photogrammetry with 3D scanning

Ever encountered disastrous results while scanning large-size sculptures or objects? Scantech’s innovative integration of photogrammetry with 3D scanning. This synergy enhances both the speed and accuracy of data collection, revolutionizing the 3D modeling process.

Explore the power of our MSCAN photogrammetry system, specially designed for scanning large-scale objects. This system can operate independently or seamlessly collaborate with our handheld 3D scanner. Elevate your scanning capabilities and overcome the challenges of large-scale projects with Scantech’s advanced technology.

MSCAN-L15 Photogrammetry System

Due to super wide scanning area, MSCAN series photogrammetry measurement system is a great accuracy booster for large-scale project like aerospace and energy field with maximum volumetric accuracy of 0.012 mm/m.

What is the best 3D scanner for your demands?

SCANTECH 3D is a global leader in 3D scanning technology, providing non-contact measurement technology of the optical scanners coupled with precision measurement within product cycle times. Discover more Scantech 3D metrology solutions for you.

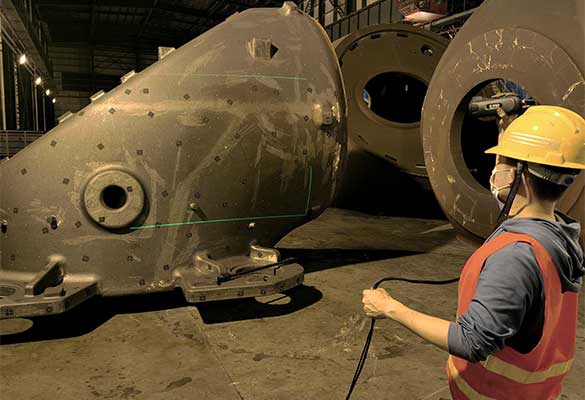

Photogrammetry system MSCAN can be combined with Scantech’s handheld 3D scanners to enhance measurement accuracy and accelerate the process when measuring very large objects, such as wind turbine blades, ship hulls, and aircraft wings. It is a better choice for improving industrial quality assurance and component development.

MSCAN provides coordinates for reference, which helps to align the data and reduce errors. MSCAN allows you to measure the dimensions and deformations of large components with high precision. For more details about MSCAN, please see the specifications below:

MSCAN-L15 MSCAN-L15 |

|

|---|---|

| Volumetric accuracy | 0.012 mm/m (0.00014 in/ft) |

| Shooting area up to | 9.4 m x 6.9 m (370.1 in × 271.7 in) |

| Device type | Industrial camera and lens(not DSLR) |

| Weight | ≤0.58 KG (≤1.28 lb) |

Cooperate with top-rate 3D scanner provider

Enable you to measure and scan everything

Photogrammetry System for Power Plant and Mold Manufacturing

Photogrammetry System for Power Plant

MSCAN photogrammetry system is a method that takes pictures of objects from various angles and directions and then processes these pictures to compute the 3D coordinates of the markers on the objects. This system can work with Scantech’s portable 3D scanners for inspection in the energy industry. It can measure and analyze large and complex objects such as wind turbine blades, pipelines, power plants, and offshore structures.

By using photogrammetry MSCAN, it is efficient for engineers and technicians to capture precise 3D models of large complex facilities such as power plants and offshore structures, which can facilitate their design and analysis. The photogrammetry system, featured a large shooting area of 9.4 m*6.9 m, can be used to improve the measurement of dimensions and geometry of power plant components and compare them with the original design specifications to verify the design intent.

Using MSCAN to measure and inspect wind turbine blades can help to ensure the optimal performance and structural integrity of parts due to its volumetric accuracy of up to 0.012 mm/m. It can identify the basic structure of the blades, and create accurate 3D models of their geometry and surface condition to identify any deviations or deformations. With its HRD mode, it can adapt to harsh working conditions and ensure high accuracy of measurement and inspection.

It can be used to measure large-scale oil pipelines for corrosion, deformation, and leakage analysis. Besides, it can help detect and quantify any defects, cracks, or damages on the surface of offshore structures, such as platforms and pipelines, and evaluate their impact on structural integrity and stability. Combined with 3D scanners, it can generate precise 3D models to evaluate different conditions that may affect the performance and safety of power plants.

Photogrammetry System for Mold Manufacturing

With MSCAN, you can enhance the inspection and measurement quality and efficiency in the mold manufacturing industry. It is especially useful for measuring large molds, as it has a depth of field of up to 6.5 m and it enables the user to access every corner of the object by moving around it freely. By using photogrammetry, manufacturers can ensure that their products and facilities meet the required standards and specifications, as well as reduce costs and risks associated with manual measurement methods.

Photogrammetry, together with portable 3D scanners, allows engineers to obtain high-precision 3D data of new molds manufactured. The 3D data can be exported as mesh files and then imported into CAD software to compare with the original design. You can use various tools and functions to edit, smooth, and refine the 3D model or analyze the geometry and dimensions of the part such as wall thickness, holes and angles. This can reduce the need for mold modification and produce qualified products.

Photogrammetry system MSCAN is easy to use and suitable for on-site inspections. By placing coded targets on the mold and scale bars in the measurement environment, you can easily achieve highly accurate measurements. It enables you to compare the actual mold with the CAD model and identify any deviations or defects. You can perform different metrological analyses, such as nominal-actual comparisons and GD&T checks to ensure the quality and accuracy of the mold.

Photogrammetry can help detect and correct any damage or wear such as cracks, dents, scratches, corrosion, and deformations on the mold surface to extend the life span and performance of the mold. With precise 3D data and intuitive reports, mold repair can be documented and recorded for future reference and improvement. Thanks to its efficient measurement, mold repair can be done in a timely manner to minimize the downtime and cost of the molds.

Scantech 3D solution with photogrammetry system designed for unique needs of different industries

Find out how our 3D scanner and photogrammetry system help.

Quality Control

What is photogrammetry and how can it help in 3D scanning? The article will give you the answer the question how we can enhance the speed and accuracy of data collection and the 3D modeling process.

Quality Control

Aircraft MRO is an indispensable requirement to guarantee the aircraft is maintained in pre-determined conditions of airworthiness for safe transportation. The project shows how to avoid accidents using 3D inspection.

Quality Control

Numerical Simulation

The structure, dimensions and process flows of wind turbine blades are the main factors that determine the conversion efficiency of wind energy. The project shows quick 3D Inspection on Large Wind Turbine Blade.

Various 3D scanning solutions for your 3D measurement needs

With Scantech's cutting-edge 3D scanning technology,

you can trust that you are using a reliable and effective 3D scanning solution that delivers high-quality results.