3D Scanning Applications in Energy & Heavy Industry

Heavy industry is a type of business that involves a high capital cost, big equipment, and low transportability. The items produced by heavy industry used to be products such as oil, iron, and construction equipment, which are essential to economic development and industrialization of economics. As a part of the supply chain of other products, energy, and heavy industry has become the foundation to produce consumer products.

High-tech 3D measurement technology is extensively used in the machinery manufacturing of heavy industry, from product design & optimization, FAI, assembly analysis, and quality control to simulation.

Scantech’s portable 3D laser scanners, optical tracking 3D scanners, and automated 3D measurement systems can be used in energy and heavy industry. The portability of our accurate 3D scanners makes it possible to measure large-scale parts, including wind power hubs, tractor chassis, and excavator arms right on-site without having to move them around. Their advanced algorithm can deliver measurement results with an accuracy of up to 0.02 mm to ensure the parts manufactured to meet the stringent requirements.

Scantech is dedicated to helping manufacturers improve efficiency and take the lead in the highly competitive market. We cater to a variety of needs in energy and heavy industry, specifically:

Guarantee the Quality with 3D Metrology Solutions

Hydropower Turbine

Wind Power Hub

Wind Power Blade

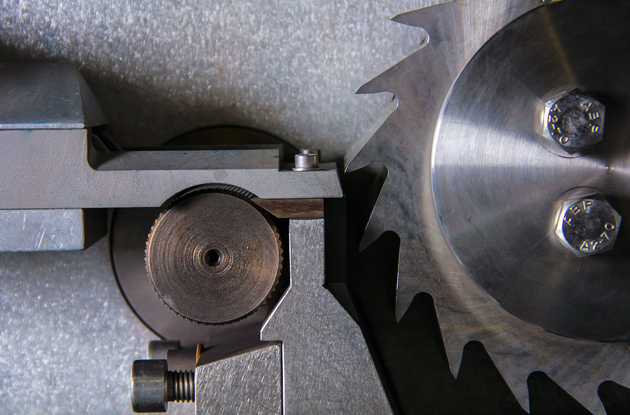

Planet Carrier Gear

Excavator Arm

Chassis

Anvil Block

Welded Coupling

NDT Measurement and Inspection for Energy and Heavy Industry

The parts in energy and heavy industry, including parts of construction equipment and farm equipment, feature large sizes, stringent requirements on GD&T, and tight machining allowances. NDT 3D measurement and inspection plays an important role in manufacturing high-quality mechanical parts and ensuring they are maintained in good working states.

GD&T Measurement

The quality inspection of parts in heavy industry falls into three main types: pre-production, in-line and final inspections. Geometric dimensioning and tolerancing (GD&T) is a crucial metric for inspection to ensure that the parts are qualified. Our high-resolution 3D scanners can capture the complete 3D data of industrial parts and obtain actual values of dimensions and tolerances including parallelism, perpendicularity, and concentricity. These data can be used to inspect newly made products or repair and optimize existing parts for extended life cycles.

Learn more >

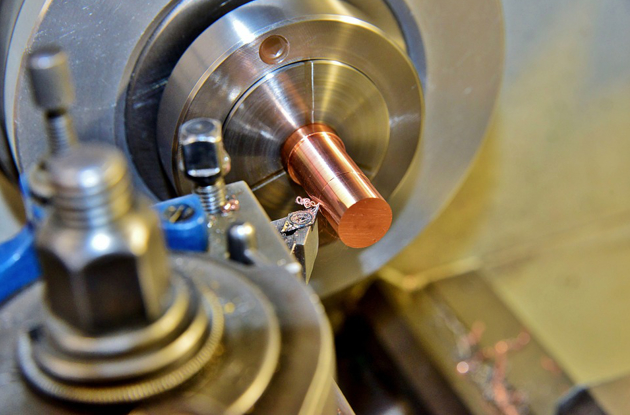

Identifying Machining Allowance

To enable parts be manufactured to the required size and accuracy, manufacturers usually add extra material to parts, which is machining allowance. 3D scanning for machinery can help to determine a decent machining allowance to reduce the defective rates of parts. Thanks to the high accuracy of our portable 3D scanners like KSCAN-Magic and optical tracking 3D scanner TrackScan-P, engineers can precisely identify the machining allowance. This way, qualified products can be made with minimal material with lower costs.

Learn more >

Defect Inspection to Ensure Quality

There may be imperfections and defects on the product manufactured, which need to be inspected and corrected. Traditional inspection heavily depends on the experiences of technicians, which is time-consuming and costly. Scantach's handheld 3D laser scanners enable engineers to identify unqualified areas quickly and accurately as they scan at high speed and measure precisely. Those unqualified areas shown in red and orange are easy to be detected. Besides, with a large number of reliable data, it is easy for users to optimize the products accordingly.

Learn more >

Reverse Engineering for Developing Products

Reverse engineering can help to accelerate the development of new products by working on existing products to draw inspirations from them. High-tech 3D scanning for energy and heavy industry can help to obtain the point cloud of existing products. When paired with reverse engineering software, the scanned data can be processed in terms of patch fitting, section creation, and curve extraction to create CAD models ready for further design. It is beneficial for designers to turn their ideas and concepts into physical objects and optimize products to better meet customers’ needs.

Learn more >

Surface Inspection of Turbines

Turbine inspection is significant for wind power tower and hydro-power generator’s overall performance and longevity. Inspect key components of newly manufactured turbines is important to ensure they function properly. It is essential to routinely inspect the parts in order to prevent the damages caused by wear and tear. Traditionally, engineers detect issues visually using cameras, drones, or their own eyes, which is tedious. Portable 3D scanners can be used to capture the data of narrow spaces and compare the data with original drawings to identify deviations and generate reports for in-tine maintenance.

Learn more >Traditional Gauge VS Scantech’s 3D Scanner

Traditional Inspection Gauge

● Tedious workflows

● Limited data collection

● Inefficient measurement

Scantech’s Handheld 3D Scanner

● Precise 3D measurement results

● Full-field data collection

● Easy operation

● Intuitive reports

● Highly portable