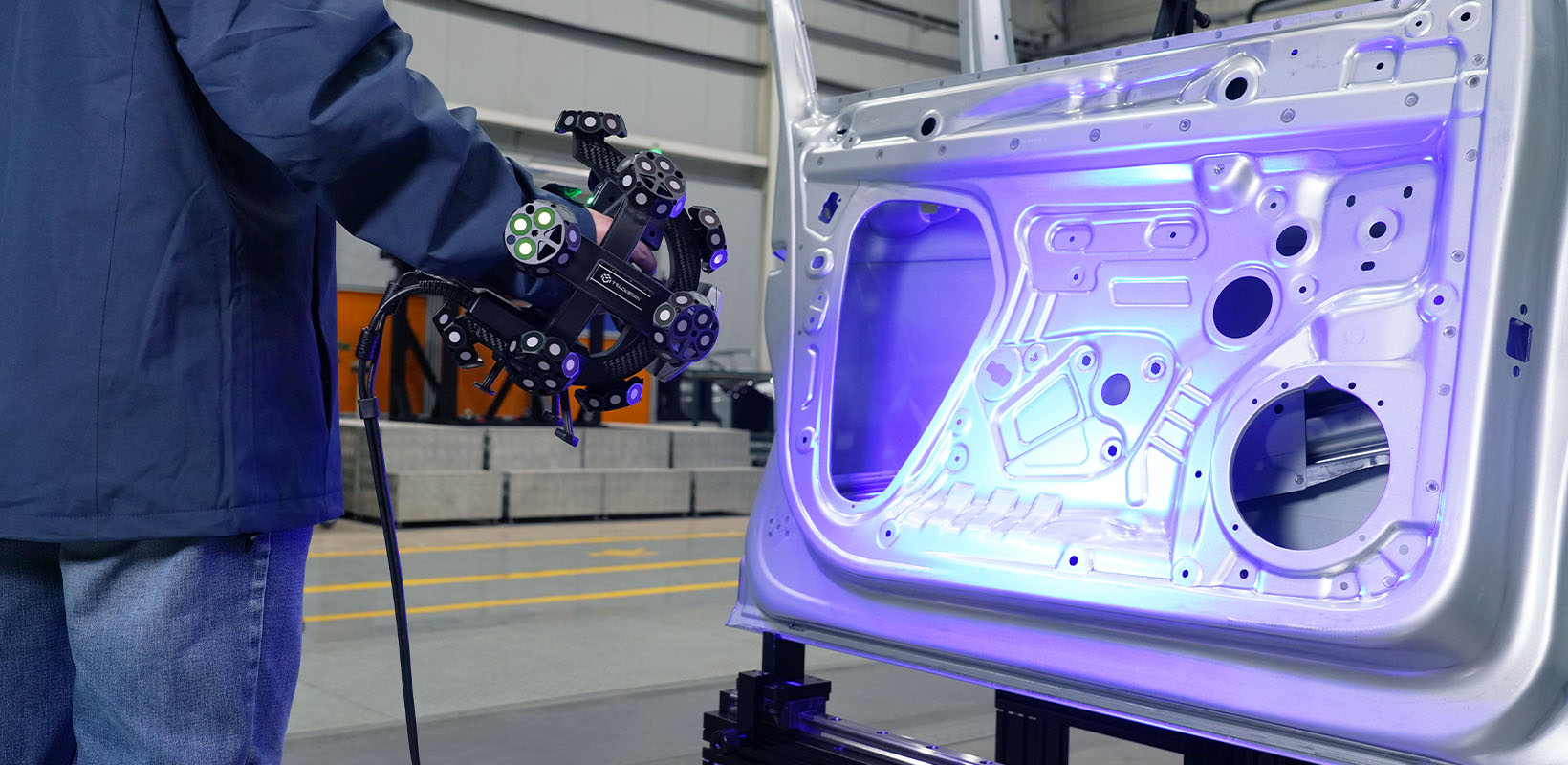

TrackScan-Sharp Optical 3D Measurement System

TrackScan-Sharp, consisting of a portable 3D scanner i-Scanner and an optical i-Tracker, is a brand-new generation of Scantech’s optical 3D measurement system for measuring large-scale parts. It brings optical measurement to a whole new level by offering a tracking distance of up to 6 meters, a volumetric range of 49 m3, and volumetric accuracy of up to 0.049 mm (10.4 m3).

Engineered with i-Tracker’s on-board processor for Edge Computing, 25-megapixel industrial cameras, and cutting-edge technologies, the TrackScan-Sharp is ideal for measuring large-sized parts or multiple parts at the same time without the hassle of moving trackers frequently.

It supports wired and wireless data transfer to cater to different industrial uses, making scanning even easier. It can also work with an auxiliary light module to inspect holes and slots. TrackScan-Sharp is optimal for efficient and stable measurements to enhance product development, quality control, and more.

Large-volume Tracking

Target-free 3D Scanning

Edge Computing

Edge Detection

Ultra-high Pixels for Intricate Details

TrackScan-Sharp tracking 3D scanning system is equipped with a brand-new industrial camera. The camera features 25 megapixels, which is 5 times that of its previous generation. Thanks to its dynamic adaptive LED algorithm, long-distance depth of field, and strong anti-interference ability, the system can automatically acquire clear images in a range as long as 6 meters.

Large-volume Measurement

Powered by its wide measurement volume and robust edge measurement algorithm, TrackScan-Sharp enables one-stop scanning of large-scale parts. There is no need for users to move the tracker frequently when measuring large parts, which ensures efficient, smooth, and precise measurements.

Edge Computing & Impressive Performance

The newly designed i-Tracker has an onboard processor for efficient image processing and data computation, which can deliver coordinates in real-time. This innovative Edge Computing saves the computer’s computing power so that it’s more capable of processing the scanned data. It optimizes the data and makes it more reliable and stable, impressing users with outstanding performance.

Remarkable Accuracy

With powerful hardware and software, TrackScan-Sharp delivers metrology-level and high-precision measurement results. This optical 3D tracking system ensures the measurement results meet high metrological demands. Thanks to its large tracking volume, which increased by around 200%, users can measure huge parts without compromising precision.

Fast 3D Scanning & New Data Transmission

Due to its optical tracking technology, TrackScan-Sharp can precisely measure parts without having to stick reference targets. Its large tracking volume allows users to measure multiple parts at the same time, thus significantly improving operations efficiency.

The 3D scanning system can transfer data both with and without wires. With wired mode, the system can send data over a long distance in line with industrial measurement standards. Optional wireless mode support applications, in different working conditions, which is convenient due to its plug-and-play operations. It can be set up quickly and operated flexibly to cater to various environmental conditions, ensuring efficient measurements.

Innovative Design

Made of aerospace-grade carbon fiber in a sphere shape, the i-Scanner is for heavy use. Its ergonomic handle can ensure the long-session use of the 3D scanner without causing much fatigue, which ensures free measurement.

The i-Tracker has an intuitive light band that shows the operating status in real time. Its hollow grille design helps cameras remain at a stable temperature throughout the scanning process.

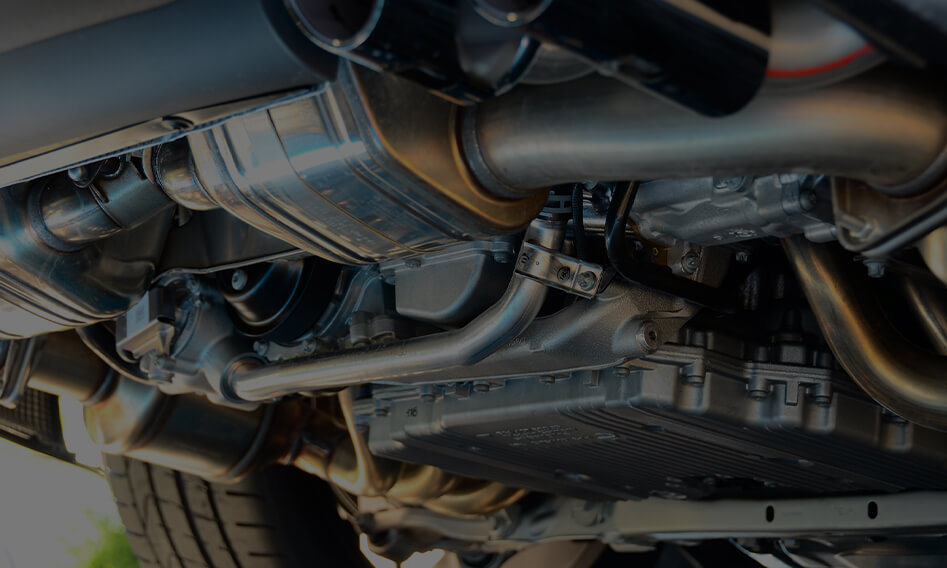

Vast Applications

Technical Specifications

| Type | TrackScan-Sharp 49 | |

| Scan mode | Ultra-fast scanning | 21 blue laser crosses |

| Hyperfine scanning | 7 blue parallel laser lines | |

| Deep-hole scanning | 1 blue laser line | |

| Accuracy(1) | Up to 0.025 mm (0.0009 in) | |

| Measurement rate up to | 2,600,000 measurements/s | |

| Scanning area up to | 500 mm × 600 mm (19.7 in × 23.6 in) | |

| Laser class | ClassⅡ (eye-safe) | |

| Resolution up to | 0.020 mm (0.0008 in) | |

| Volumetric accuracy(2) | 10.4 m³ (Tracking distance 3.5 m) | 0.049 mm (0.0019 in) |

| 28.6 m³ (Tracking distance 5.0 m) | 0.067 mm (0.0026 in) | |

| 49.0 m³ (Tracking distance 6.0 m) | 0.089 mm (0.0035 in) | |

| Tracking Distance per i-Tracker | 6000 mm (236.2 in) | |

| Volumetric accuracy (with MSCAN photogrammetry system) | 0.044 mm + 0.012 mm/m (>6m) (0.0017 in + 0.00014 in/ft) |

|

| Hole position accuracy | 0.050 mm (0.0020 in) | |

| Camera pixels of i-Tracker | 25 MP | |

| Stand-off distance | 300 mm (11.8 in) | |

| Depth of field | 400 mm (15.7 in) | |

| Part size range (recommended) | 0.1 m-12 m (3.9 in-472.4 in) | |

| Operating temperature range | 0-45 °C (32℉-113℉) | |

| Operating humidity range (non-condensing) | 10-90% RH | |

| Interface mode | USB 3.0, Network Interface | |

| Certification | CE, RoHS, WEEE | |

| Patents | CN106500627B, CN106500628B, CN206132003U, CN204854633U, CN204944431U, CN204902788U, CN204963812U, CN204902785U, CN106403845B, US10309770B2, CN204854633U, CN105068384B, CN105049664B, CN106403845B, CN111694665A, CN214375417U, CN214379242U, CN214379241U, CN214149174U, CN109000582B, CN112802002B, CN210567185U, CN211121096U,CN114001671B, CN114001696B, CN114554025B, CN114205483B, CN113514008A, US10309770B2, US11060853B2, KR102096806B1, EP3392831B1, CN218411072U, CN115325959B, CN218103238U, CN218103220U, CN113670202A, CN113766083A, CN114189594A, CN114627249B, CN115493514A, CN115493512A, CN115451862A, US11493326B2, CN115695763B, CN115690333A, CN307756797S, CN218584004U | |

|

(1) ISO 17025 accredited: Based on VDI/VDE 2634 Part 3 standard and JJF 1951 specification, probing error (size) (PS) performance is evaluated. |

||

Ready To Get Started?

Rebuild our 3D world with the most advanced 3D scanning system available.

Request A DemoWhat’s the best 3D solution for your business?

Boost your business with 3D digitization technology.

Ask An Expert BrochureHigh-tech 3D Scanners

Scantech’s handheld 3D scanners power the 3D scanning services. These instruments can obtain precise point clouds, which can be triangulated into a polygon mesh or STL file.

Due to their high precision, versatility, and portability, they can fulfill various metrology-grade 3D scanning projects.